Windproof membrane: affordable home protection

Content

During the construction of the roof and the arrangement of the ventilated facade, a windproof membrane is required to protect the heat-insulating material from adverse climatic factors. It is notable for its affordable price, easy installation and durability. Manufacturers produce a windproof film with a different number of layers and technical characteristics. A wide assortment allows you to choose hydro-, windproof membranes in optimal accordance with the tasks at hand.

Warming of facades of houses and roofs is carried out using mineral wool insulation material. Its feature is the structure of light and long fibers, which during operation are blown out by air currents. Without protection, for several years, the insulation can lose a significant part of its volume, as a result, the thermal characteristics of the building will deteriorate to unacceptable values. To prevent this, use wind protection.

Previously, for this, a glassine or a plastic film was used for a long time. These materials have a significant drawback - low vapor permeability. During operation, water accumulates on the inside of the glassine and polyethylene, with which the insulation is saturated. As a result, the thermal conductivity of the insulating material increases and the building becomes cold. These disadvantages are absent in hydro-windproof membranes.

Membrane Functions

The windproof membrane created from polyethylene and polyester performs the following functions:

- protects fibers of heat-insulating material from a wind stream;

- helps to reduce heat loss;

- fixes and stabilizes light heat-insulating material;

- protects a heater from atmospheric precipitation.

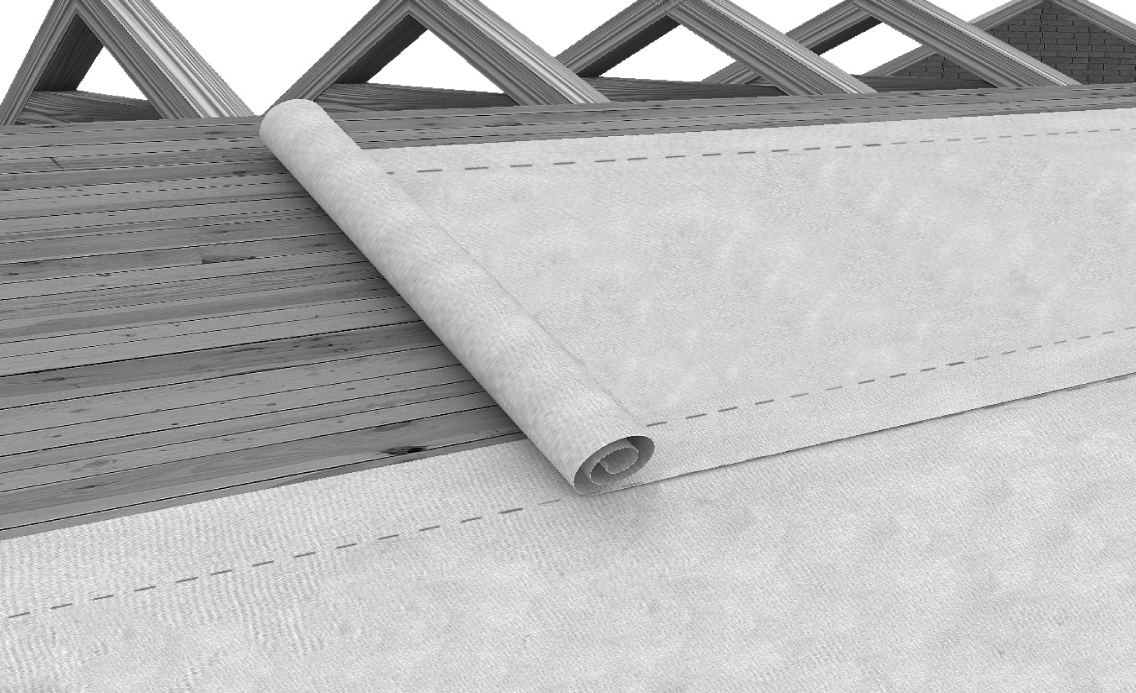

The membrane is laid on the outside of the insulation on top of the frame used for the installation of insulation boards. It is fastened with the help of a construction stapler, it is always lapped and glued with special adhesive tape.

Membrane Applications

The high demand for such material as a windproof membrane is caused by the popularity of frame housing construction, ventilated facades and residential attics. All these structures are multilayer, the use of insulation allows not only to improve the thermal characteristics of the building, but also to reduce the load on the bearing walls and foundation. Since mineral wool insulation is a part of the “pie” in most cases, it is protected from wind, steam, condensate.

The main areas of application of windproof membranes:

- construction of insulated roofs and attic floors;

- ventilated facades;

- floor floors;

- floors laid on lags;

- frame partitions.

Windproof waterproofing film does not significantly increase the cost of work, while performing important functions, extending the life of the insulation.

Types of windproof membranes

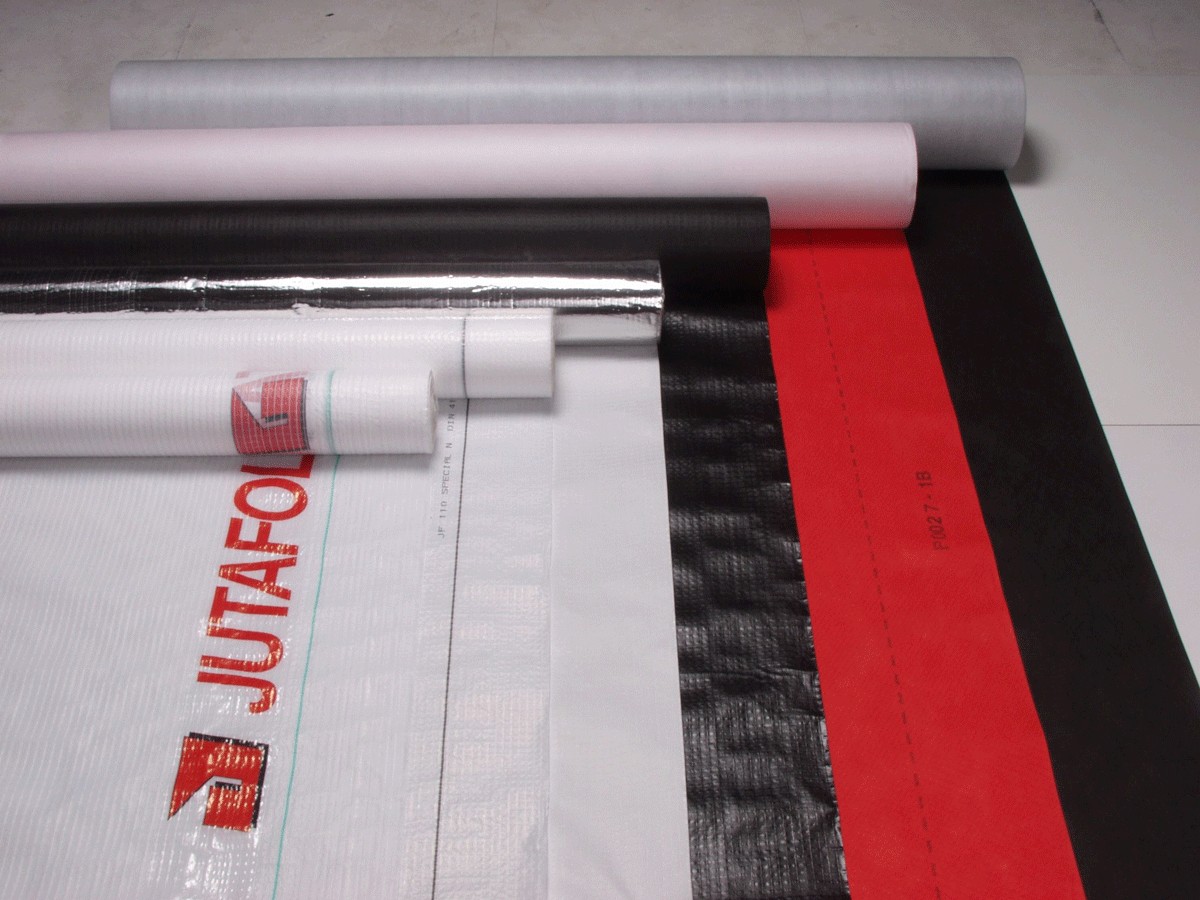

A single-layer windproof membrane made of glassine and polyethylene is used today in budgetary private construction. The most popular are two-layer and three-layer membranes made of polyester and polypropylene.Thin layers are combined into a single structure using ultrasound, which provides the material with maximum functionality. During installation, the vapor-permeable windproof membrane is subjected to severe mechanical stress. Gusts of wind, structural parts of the frame, protruding nails can tear the material, which leads to a violation of tightness and loss of functionality. For this reason, builders prefer three-layer membranes, one of the layers of which is specially designed to provide high strength.

Windproof films are divided into moisture-proof and superdiffusion membranes. Waterproofing and windproof films have good vapor permeability, but are able to protect thermal insulation only from splashes, snow powder. Their water resistance does not exceed 200-250 mm of water column. The diffusion membrane has a more complex structure, due to which it has high strength and the ability to withstand 1000 mm of water. Such films can be used as a temporary coating for roofs - they will protect the house under construction from rain and light snow, gusts of wind.

The diffusive windproof membrane for walls increases the life of the insulation several times. It is recommended for use in the construction of ventilated facades at critical facilities and high-rise buildings.

Benefits of using windproof membranes

Windproof membranes have the following advantages, expanding the scope of this material:

- easy installation at any time of the year;

- environmental safety for humans and the environment;

- fire resistance;

- resistance to high humidity and solar ultraviolet;

- resistance to temperature extremes and severe frosts;

- elasticity and strength;

- long term of operation.

Membranes do not emit harmful substances into the environment, including when heated by several tens of degrees. Since most films are vapor permeable, they create maximum comfort in a room whose walls are protected by this material from external factors.

Most often, windproof membranes are used in structures with a ventilated gap. The air flow in this case can be compared with the effect of a blacksmith forge, which is capable of inflating smoldering coals. In the event of a fire, powerful fire protection is necessary and for this reason, substances that suppress combustion are added to the membranes.

During the installation of a roof or facade, there are often problems with the delivery of finishing material. We didn’t have time to deliver the metal tile, siding, corrugated board or porcelain tile in time - it doesn’t matter, the membranes resistant to solar ultraviolet and moisture will reliably protect the insulation, roof structures for several weeks from the negative effects of the environment.

In the event that a pause is planned before the final stage of work, it is necessary to lay in the project the use of superdiffusion windproof membranes. They can serve as a temporary roof for several months.

Features of installation of windproof membranes

To ensure the functionality of windproof and waterproofing films, they must be correctly mounted. Most manufacturers of this material complete each roll with instructions in accordance with which it is easy to lay the membrane on the rafter system or fix it on the facade of the building.

Leading manufacturers print their logo on one side of the membrane, this is done not only for advertising purposes. Putting the film needs to be printed out, and the reverse side is applied directly to the insulation. In this case, the waterproofing of the heat-insulating material and the vapor permeability of the whole “pie” are provided. In the absence of a logo on the film, it can be laid on the insulation on either side.

Windproof materials are used in the construction of insulated roofs and in the construction of attics. When using inexpensive two-layer films, it is necessary to create a double ventilation gap: there should be a space of 5 cm between the insulation and the membrane, there should also be a gap of 5 cm between the roofing material and the membrane. When using superdiffusion membranes, this requirement can be neglected.

When laying the membranes on the walls, it is necessary to start the movement from the bottom up, with an overlap of 10-15 cm, which is glued with a special adhesive tape or mounting tape. A number of manufacturers produce a film with an adhesive layer, which greatly simplifies the joining of two paintings. Do not leave mounting holes or cuts - this will violate the tightness of the wind insulation and waterproofing system. If there are protruding elements, then the cuts for them must be sealed.

Windproof films are actively used in the construction of frame houses. They are most often built on a pile or light strip foundation. To protect against heat loss, the floor of the first floor is insulated with a mineral wool stove. It must be protected from blowing out the fibers, so a windproof membrane is laid first, and on top of it is thermal insulation, which is protected from leakage by a waterproofing film. Use for frame house building insulation and the formation of the attic floor. In this case, the thermal insulation is protected from above by blowing the fibers in a draft.

Windproof membranes are an inexpensive building material that can provide a high level of comfort in the home. The use of these films not only protects the thermal insulation, but also extends its life. A properly mounted membrane can delay the costly repair of a ventilated facade or attic for decades. It will reliably protect the house from wind, high humidity and will become an additional obstacle to the fire.