Puttying the floor: how to make wooden and concrete floors perfect

Content

Wood flooring has always been in demand and relevant. Moreover, even now, along with more progressive and unusual solutions for the home, it is wood finishing that is the most popular option.

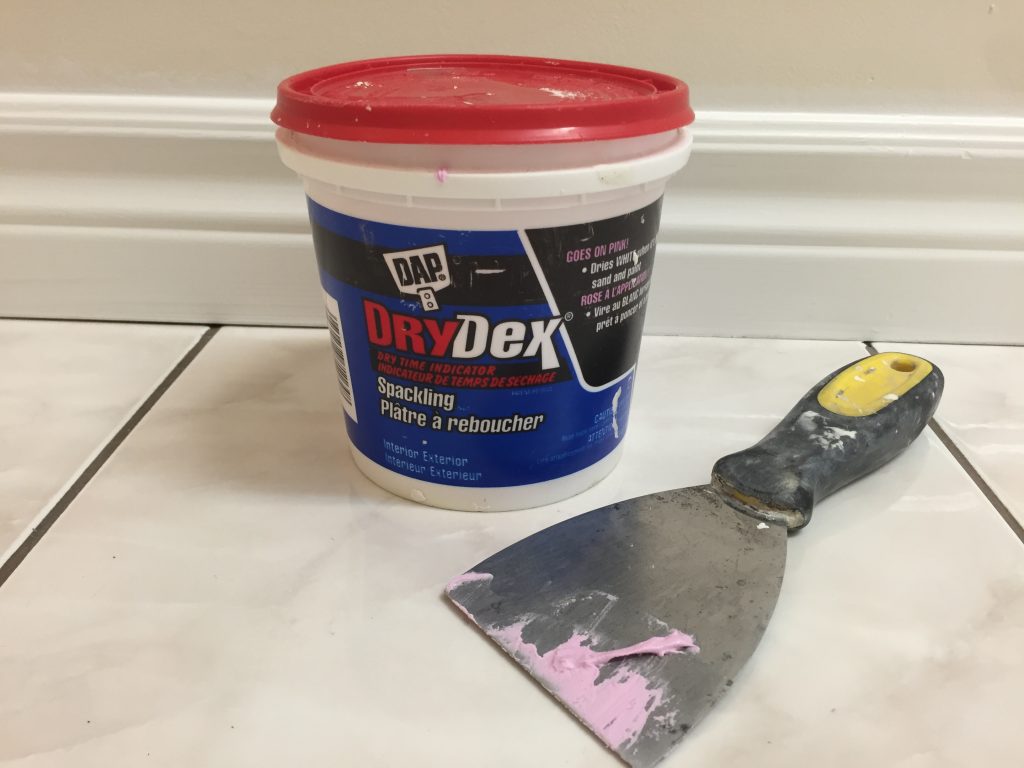

To improve the technical characteristics of the board, it is necessary to adjust the woodwork from time to time. For this, wood putty is most often used for flooring. This building material is striking in its versatility, as it is used for many purposes.

How does putty work for wooden surfaces?

Putty for a wooden floor with your own hands or with the help of specialists is required not only if the floor covering is completely changed. A good putty is able to significantly update the old flooring. High-quality redecoration without this material is impossible.

Putty and a relatively new floor. This is necessary to hide all defects and cracks in the floor covering. No matter how spectacular the color is, no matter how enticing the refined texture is, if the surface is not smooth enough, the whole aesthetic effect is lost.

Why putty concrete floors?

It would be a mistake to assume that the putty of the floor is necessary only if it is necessary to work with wooden parts. In fact, putty for concrete floor is also widely used. Concrete floors are characterized by high strength, but in the presence of even the smallest defects or joints that were poorly painted before, the canvas will begin to rapidly collapse.

If low-quality materials were used for the manufacture of concrete or the construction work technology was violated, it is simply necessary to process the floors with various putties.

Treated surfaces have a number of special advantages:

- High level of wear resistance;

- Optimum erosion resistance;

- Resistance to abrasion, various damage, aggressive mechanical stress;

- The surface is not afraid of chemicals and moisture;

- The period of exploitation of the floors increases several times.

A well-selected putty for concrete floors will make the surface perfectly smooth and quite attractive. After all the work is done on the correction of the canvas, you can proceed to the next stage - the installation of other building materials or the installation of decorative elements.

Putty mixes for concrete

Choosing a putty is not so simple. First you need to study the species diversity and assortment of products of a similar profile.

All putties are divided into two global categories: base and finish. Also, modern manufacturers offer potential buyers materials of a universal type (intermediate). They are suitable for any type of operation, as well as “take root” on any surface.With their help, puttying of the floor under linoleum is carried out, the canvas on the wooden floor is improved, the operational characteristics of the bulk floor are improved.

Putty material for component composition for concrete surfaces

Indeed, skillfully selected and high-quality putty can smooth any surface, mask even the largest gaps. According to the component composition for these purposes, you can choose putties of the following types:

- Cement;

- Based on lime;

- Oil;

- Glue;

- Varnish;

- Polymeric nature or acrylic.

Often, they try to improve the standard formula due to polyester and polyurethane additives, as well as other components that, to one degree or another, improve the quality of the finishing material. Puttying can be carried out both in liquid and in thick formulations.

The first type is represented by self-leveling compounds, which process exclusively concrete surfaces. Such mixtures under their own weight are distributed on the floor, filling the cavity of the gaps, creating a perfectly smooth canvas. A similar technique is also called “solid putty”.

What to choose for wood flooring?

Both basic and finishing putty for leveling the floor can be intended exclusively for wooden coating. However, other canvases can be puttyed with similar materials. It all depends on the characteristics of the composition and individual characteristics of the floor.

In order to improve the wooden floor, the following types of putties are best suited:

- Acrylic putty;

- Based on various solvents;

- Oil analogues;

- Polymer putty (also used for lamination).

Cement and known putty are not used for the treatment of wooden surfaces. Adhesive formulations are also extremely rare.

DIY putty mixes

Wood can also be processed with putty, created with one's own hand. How to make and which components are best to choose, you can see on any building portal. However, not every recipe is successful, and it will be necessary to check the quality of the finished putty during practical experiments.

To make a putty for wood, you can safely use the following components in the specified quantity:

- Drying oil or any analogue of it (about 600 gr.);

- Clay of vegetable or animal origin (150 gr.);

- Turpentine (120 grams);

- Desiccant in liquid form (about 25 grams).

You will also need chalk (dry and especially carefully sifted) and soap. Glue of animal origin is slowly heated, soap is added there. Gradually introduce all the steel components of the future putty. Chalk additive should be mixed with the composition in the last turn. The mixture is thoroughly mixed, waiting until the home-made putty acquires the necessary density.

An important rule: the mixture for screed wooden floors should not be cold. With its help, the floor covering is leveled either immediately after manufacture or preheated in a water bath.

Gypsum mixtures

To quickly choose a putty, most buyers do not pay due attention to the characteristics of the composition, but prefer the most popular option of all. Gypsum mixture is the most popular putty for the floor.

Main advantages:

- No shrinkage;

- Extremely low price;

- The ability to make a perfectly even screed for linoleum flooring and other coatings.

Only one layer of selected gypsum mixture is able to solve all the finishing tasks. The only drawback is that the materials cannot be used for rooms where it is always very humid. These are bathrooms, toilet, kitchen.

Acrylic Blends

If you need to improve the surface of the "fresh" floor under the laminate, most often use acrylic.The mixture allows you to get rid of deep gaps, eliminate seams and traces of the removal of reinforcing elements, as well as other specific damage.

Putty mixtures are practiced for finishing any wooden surfaces. Plywood is also a specific form of wood. That is why the laying of plywood on the floor is supplemented with puttying. This is necessary in order to lay new linoleum on top of plywood paintings.

The main advantages of the material:

- Optimum filling of voids, cracks, elimination of other defects;

- Strengthening complex areas by contracting damaged fragments;

- The ability to create a perfectly smooth and durable canvas, ready for further processing;

- Resistance to moisture, chemicals, germs, mold, fungi.

Acrylic is practical and durable, it is not afraid of high temperatures. Putty shows all its technical characteristics after complete solidification.

Solvent based putties

What putty to choose, can advise an ordinary consultant in a hardware store. So, for example, putty plywood is often carried out using putty based on special solvents. The product works well on parquet floors and various wood substrates. Manufacturers focus on the fact that this particular type of mixture is suitable for the improvement of warm and bulk floors.

Waterproofing analogues

This is a special category of flooring mixes. Waterproofing materials are used as an independent coating. If the repair is carried out with a rather meager budget, this will be a good solution in order to save money.

The composition of the putty is very rich. Hardeners, various target additives, polyurethane components and much more are concentrated here. The mixture is widely used for work in bathrooms, saunas, baths, steam rooms, showers.

When choosing a putty for a wooden, concrete, “warm” or bulk floor, you always need to take into account the properties of each concrete composition, correlating with individual requirements and wishes. Finishing materials are chosen not only for price and operational characteristics, but also taking into account the color palette and texture.