Sealant for outdoor use: everything you need to know

Content

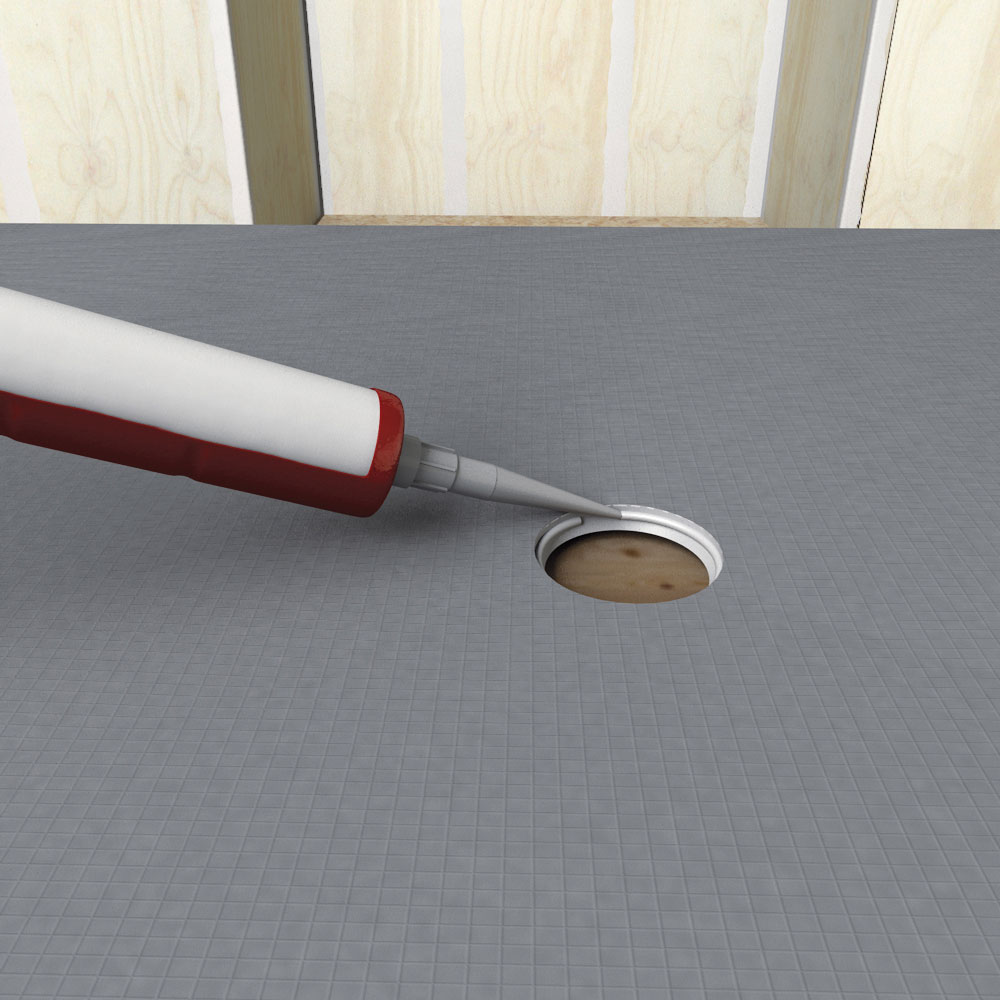

Sealant for outdoor work - the necessary material for sealing joints and seams, window openings (including for PVC windows), working ventilation systems, domes, greenhouses. For facade exterior work, only those sealants that are resistant to moisture and temperature extremes are suitable. Construction stores offer a choice of many different types of sealing materials.

The main types

All types of sealants, regardless of performance, fulfill one important mission: they seal joints, protecting the structure from moisture “under the seam”. Depending on the set construction goals, a specific type of sealing material is already selected:

- Acrylic sealant for wood and other contact surfaces;

- Silicone sealant for outdoor use;

- Two-component material for seams and joints;

- Polyurethane sealant for outdoor use.

The choice of sealant is an important process. The selected construction sealant should not only be of high quality, but also meet a number of specific requirements:

- The elasticity of the building and finishing material;

- Optimum adhesion to surfaces, contributing to good contact of the sealant with facade materials;

- Environmentally friendly and safe composition;

- Simplicity and ease of use, the ability to quickly carry out all the proper manipulations;

- Accessibility in terms of price, the ability to choose a sealant for windows, walls, joints, taking into account the color of the facades;

- Maintainability of building materials;

- A specific appearance (for example, transparent for delicate work);

- Reliability.

A good facade sealant will allow you to work in any climatic conditions. Upon completion of the finishing work, the facade elements should not be afraid of moisture, and also respond to temperature changes.

Features of silicone sealing

Silicone sealants are convenient for the most complex or delicate jobs. Silicone-filled sealants consist of plasticizers, dyes, various additives. Despite this, the product is safe.

It is worth noting a number of features of silicone used as a basis for sealants:

- High degree of elasticity necessary for good and quick filling of gaps and seams;

- Excellent strength characteristics, allowing to carry out the most complex outdoor work in conditions of especially intensive use;

- Quality silicones are not afraid of a sudden change in temperature;

- High-quality building sealants with a good composition are characterized by a high degree of adhesion;

- Silicone sealant is frost-resistant.

It is worth noting that high-quality sealant is waterproof. When choosing a material for outdoor decoration, you don’t have to worry about the possible difficulties associated with the compatibility of finishing paintings. Suitable silicone sealant for granite, copes well with the finishing of joints on concrete, is used to seal metal or stones, it is convenient to work with plastic windows.

Species features

For silicone sealants, some features are characteristic. Distinguish between neutral and acidic species.Neutral sealant is best used for restoration work in swimming pools, in bathrooms or in the kitchen. A small amount of silicone compound may be needed to repair plumbing.

For exterior use acid species. They lie well on the stone and interact with metal structures. You can also use acidic analogues to work with wood.

The tree is characterized by those qualities that are not inherent in any other type of material. That is why silicone compounds not only seal, but also impregnate the canvas. This allows you to maintain the appearance and performance of wood for as long as possible.

It is also worth noting that frost-resistant silicone material can not be stained or restored. For this reason, manufacturers produce sealants for facade decoration in various colors. The buyer can choose the color of the material that suits him best. For example, brown color is suitable for wooden surfaces. A white or transparent look is good in working with a PVC window. You can find colored compounds "under the stone."

Acrylic Sealing

Acrylic sealants are used by adherents of environmentally friendly materials. There are waterproof and non-waterproof species. Moisture-resistant acrylic sealant for wood and other surfaces is used in roofing and window openings. The material is frost-resistant, able to withstand low temperature loads (up to 30 degrees). Non-waterproof materials are used to secure sedentary structures.

Acrylic sealant for wood and other surfaces has the following advantages:

- Material is often acquired by a construction company because of its simplicity and ease of use;

- External acrylic for sealing is sold at a low price;

- Good adhesion

- Acrylic sealant for wood is resistant to high temperatures, does not ignite;

- Not afraid of ultraviolet radiation;

- Good at staining. You can choose a neutral material for decoration, modifying its color or shade as necessary.

However, acrylic sealant for wood and other surfaces is afraid of external temperature differences, and also loses its sealing properties due to the harmful effects of moisture. Another important point: acrylic is suitable only in gaps with an opening of less than 15%. Otherwise, delamination may occur.

For acrylic sealants to do their best, they need dryness and warmth. It takes about 24 hours to completely harden the sealant. The most expensive in this category are transparent formulations.

Polyurethane sealing

Polyurethane materials are ideal for outdoor use. When choosing which sealant to purchase so that it combines with different surfaces, it is worth paying particular attention to materials with a polyurethane composition.

Working with it, you can not only work with joints or give tightness to wide seams, but also use the material as a reliable glue that fastens any parts. The uniqueness of polyurethane sealant lies in the fact that it is not only not afraid of moisture, but also gets stronger when it comes into contact with it. Today it is the best universal material for external use in particularly humid regions.

Special advantages

Polyurethane adhesive sealant is a one-component polyurethane that is particularly flexible. It can be chosen as a surrogate for polyurethane foam. One material is able to replace at least three types of building mixtures to perform various tasks.

Sealants-adhesives with a polyurethane base are distinguished by the following outstanding characteristics:

- Elasticity;

- Strengthened adhesion, especially important for the outer sheet;

- The material is water resistant, from contact with moisture it becomes even better;

- The mass for external sealing quickly hardens;

- Polyurethane is not afraid of UV radiation;

- Does not emit toxins and other harmful components;

- Long term of operation.

Frost-resistant sealant for concrete, ceramics, plastics, wood lends itself well to painting. Even if you use polyurethane exclusively as glue, the facade will still need to be painted, adjusting the nuances of the exterior. Moisture-resistant outer surface perfectly interacts with any kind of paint.

You can choose the right tone and make the polyurethane finish color, or choose a contrasting shade that will go well with granite, stone, wood, will give special appeal to metal or plastic surfaces. The most popular options are dark brown, tones of white or beige, or a completely transparent sealant.

Siliconized formulations (acrylatex)

If you need a frost-resistant composition and a strong waterproof base, you should choose silicone compounds. In fact, sealant for stone, plaster, glass, wood and siding has the same characteristics as acrylic.

Strong and reliable composition perfectly tolerates temperature changes, humidity, prolonged exposure to ultraviolet rays. Acrylatex sealants are suitable for all types of sealing: both external and internal.

A particular advantage, why it is worth choosing siliconized compounds, is the ability of the composition to adapt to deformations. The base of the seam remains tight, but quite elastic. After solidification of the mass, the surface can be painted. It is better to use latex paints. To create a colored canvas with a deep intense tone, it is better to choose a latex coloring composition.

As always, the actual colors are: dark brown, light brown, close to a beige palette, white, black. Many would prefer a transparent option that suits all occasions.

Bituminous sealant: special look

To repair the roof, it is better to choose a brown bitumen sealant. It is based on rubber and bitumen. We can say that this is the founder of all sealants, the first product that was used to insulate and seal the external foundation, roof and drainage systems.

Of course, you can choose a more expensive transparent sealant. However, this is not always justified. Simple brown bitumen-based sealants allow you to seal any cloth. The composition is not afraid of precipitation, aggregates do not dissolve in liquids.

Bituminous compositions are highly elastic. On the one hand, this is an undeniable advantage. On the other hand, it is not always acceptable to use brown color in the exterior of the building, and sealant should not be painted.

What we choose should last a long time. If we seal the facade of the building and any external surfaces, the choice of sealing compounds is approached with all responsibility. In the first place there should always be operational characteristics, and only then aesthetics and the pursuit of fashionable novelties (transparent material, exclusivity, original goods on the market).