Decoration Acrylic Sealant: Composition Capabilities

Content

During repair and construction work, acrylic sealants are actively used. The main advantage of these formulations is their affordable cost, simple application and good technical characteristics. This is one of the most popular materials for working on concrete and wood, sealing joints between logs and ceramic tiles.

Acrylic-based sealants replaced gypsum and alabaster, as well as putties and putties, from the arsenal of builders. Due to their low price and properties, they can compete with silicone-based sealants. The material has its drawbacks, considering which serious problems can be avoided. The main purpose of all grades of acrylic sealants is to fill voids in fixed and inactive structures.

The main advantages of acrylic sealants

Sealants based on acrylates are created, which affects the technical and decorative characteristics. As a solvent, after evaporation of which the composition acquires its practical properties, water is used. The classic acrylic white sealant has the following important advantages:

- dimensional stability of the seal after application;

- long term preservation of their properties - at least 10-15 years;

- hardened sealant well tolerates vibration;

- retains its color throughout the life of the product;

- antifungal components protect against the formation of fungi and mold;

- environmentally friendly composition that does not have unpleasant odors;

- high level of fire safety;

- high-quality painted with acrylic or oil paints;

- affordable cost.

Manufacturers produce frost-resistant sealants, moisture-resistant compounds that can be used in bathrooms and other rooms with high humidity.

Various grades of acrylic sealants are used, the classification of which can be based both on the scope and color. By their hue, the compositions are white, transparent and colored. After applying acrylic sealant, it practically does not change its color. If transparent silicone becomes cloudy, then acrylic does not lose its light transmission. This property can be used when working with glass surfaces, decorating furniture.

An important advantage of acrylic sealants is their ability to stain. Silicone joints have low water absorption, the paint does not fall on them, and the white surface does not remain long, acquiring a characteristic yellow hue. For this reason, when finishing work, builders prefer to use acrylic sealants to seal joints.

Disadvantages of Acrylic Sealants

One of the main disadvantages of universal acrylic sealants is their low water resistance. For this reason, it is recommended to use a specialized acrylic sealant for the bathroom when working in this room. Universal compounds developed on the basis of water dispersion, therefore, under the influence of high humidity they are destroyed.Acrylic sealants are not suitable for systems with high loads. Squeezing or stretching regularly will break the seams.

Complicated relationships in acrylic sealants with temperature conditions. Manufacturers produce frost-resistant compounds used for outdoor work. The maximum temperature at which acrylates retain their characteristics reaches + 80ºС. According to this indicator, they are inferior to silicone compounds, but are quite suitable for operation in all climatic zones. On the other hand, the frost-resistant and heat-resistant properties of universal acrylic sealants can become irrelevant in a situation where the surface temperature on which they are applied will experience temperature fluctuations of 10%. In such conditions, the joint sealant cracks, begins to crumble, losing its practical and decorative properties.

Loss of elasticity and technical characteristics occurs during the operation of universal grades in the cold. They are trying to use them to reduce the cost of repairs, but it is better to use frost-resistant compounds. Only in this case can seams and joints be sealed without loss of elasticity regardless of operating conditions.

Main technical parameters

The scope of use of any building material is determined by its basic technical parameters. Acrylic sealant has the following characteristics:

- recommended seam width - no more than 5 cm;

- recommended seam thickness - 50% of the width;

- flow rate - a standard tube with a volume of 325 ml is designed for 5 linear meters of seams 10 mm wide and 6 mm thick;

- Recommended application surface temperature - from +5 to + 32ºС;

- operating temperature range - from -40 to + 80ºС;

- staining - 21-30 days after application;

- complete hardening time - 21-30 days at an air humidity of 50-60%;

- setting with the surface - up to 60 min;

- frost resistance - up to 5 cycles.

When planning work, all technical parameters must be taken into account, only in this case it will be possible to guarantee the high quality of the work performed.

Applications for acrylic sealants

Joint sealing operations can be carried out with water-resistant and non-water-resistant acrylic-based compounds. Experts recommend using them for internal work. For external use only frost-resistant compounds are suitable, with which you can work indoors.

The non-moisture resistant one-component sealant, due to its properties, can only be used in dry rooms with normal humidity. It is used in the installation of wooden, plastic skirting boards, foam fillets. Sealant for expanded polystyrene tiles is used when working with drywall.

Using acrylic, it is possible to mount decorative elements on concrete or brick walls, to close the joints between tiles or clinker. The sealant provides a high-quality connection of parts made of wood, due to good adhesion to this base. It is actively used in the repair of furniture at home.

Acrylic-based waterproof sealant is used much more widely, it has excellent adhesion to the following substrates:

- wood and plywood;

- tile and ceramic brick;

- aerated concrete and foam concrete;

- concrete plates.

Sealant is used on rough, porous and smooth surfaces. You can use it in the kitchen and in the bathroom, where there is a higher humidity than in other rooms. It is a good window sealant used to seal joints in wooden frames.

Acrylic sealants are used to seal joints in the laminate and floorboard, the manufacturer produces a wide range of products with a shade similar in color to different types of wood. Due to this and good adhesion to wood, such compositions are widely used for sealing joints between logs.Residential houses, summer residences, baths, motels and rest houses are being built from environmentally friendly material. At the same time, traditional technologies are not always used to seal the seams that are formed between the logs. Previously, hemp was used for log cabins, but the potential customers did not always like the durability and quality of such a seal.

Acrylic sealant for wood is used, which is close in color to the color of the wood used. It is recommended to use a sealant for outdoor use, able to withstand high humidity and condensation. Internal and external seams are closed, this helps to prevent drafts, dampness, and insects from appearing in the house. Seams between wooden logs and foundation concrete are also treated, since acrylic has excellent adhesion to these substrates.

Acrylic sealant is an ideal material for the log house, with its help they finish. Also, compositions with a touch of wood are used when repairing houses from profiled and glued beams or cottages with finishing with a block house, lining, imitation of timber. It is used to seal holes formed when knots fall out, as well as other flaws in the wood surface. During operation, the tree is drying up and cracks are formed between the panels of the eurolining or blockhouse, which can also be eliminated with acrylic based sealant.

Sealant is used to fix ceramic and tile to surfaces, including in log cabins. This material is easier to use than specialized adhesives. When laying tiles, there is enough time for adjustment, which allows to ensure high quality work. The same composition can be used for jointing, moisture-proof sealant will reliably protect the inner surface of the tile from high humidity. White sealant is most in demand - this is a universal shade that will suit the most diverse collections of tiles in shades.

Sealant for concrete is used in the repair of window sills made of this material. With its help, cracks are closed, seams between the slab and the wall. Sealing the connection between the windowsill and the wall will ensure that there are no drafts in the house and will prevent the formation of dampness.

Manufacturers produce special sealants for windows, they can be applied to concrete and wood surfaces. Accordingly, the scope of this material is expanding, for example, this acrylic can close the cracks in the logs, as well as between the wall and the floor. Compositions designed for laminate flooring, a popular floor covering, are no less effective when working with euro-lining, block house, imitation of timber, plywood and MDF.

When choosing a sealant, it is necessary to pay attention not only to the water resistance of the composition, but also to its elasticity. If the surfaces to be sealed can be subject to vibration, it is better to apply a frost-resistant composition. Its elasticity is much higher thanks to special additives that prevent the composition from collapsing under the influence of low temperatures.

Acrylic compounds, some experts recommend for roofing. At the same time, low resistance to water flows, temperature changes and high temperature is completely forgotten. Roofing material in the sun can heat up to 80-90 degrees, which is critical for acrylic. You can use acrylic sealant only when installing wooden skylights, sealing the joints between the frame and the rafter system. For other types of roofing, various brands of waterproof silicone sealants are more suitable.

How to choose acrylic sealant

The sealant has good adhesion to most materials, but plastics are an exception to this rule. Provide a good grip with them can only specialized compounds.If these are not available, then it is imperative to use a primer as an additional layer between plastic and acrylic sealant.

Moisture-resistant compounds used in the bathroom, in the kitchen or on the balcony must contain fungicidal additives. In this case, mold and fungi will not form in the filled joints, which can destroy the seal. To seal aquariums, it is recommended to use specialized sealants. They have increased resistance to aggressive environments, while being absolutely safe for living organisms.

Sealants are often used to seal masonry fireplaces, stoves and pipes. For these purposes, only specialized formulations capable of withstanding high temperatures should be used. Acrylic sealants are not suitable for these purposes, since the limit of their heat resistance does not exceed + 120ºС.

Features of the use of acrylic sealants

How to apply single-component acrylic sealants? These are some of the easiest materials to use, the method of application depends on the form of delivery. Sealants are packed in tubes or plastic buckets. Tubes are the best option for applying to narrow seams formed by ceramic tiles. Plastic buckets are relevant for large volumes of work, for example, when sealing joints between logs of a log house.

Acrylic based sealants do not require professional skills. It is enough to have a desire to do the job efficiently, and simple hand tools should be at hand. Regardless of the form of packaging and the type of one-component sealant used, high-quality surface preparation is required. At the seams should not be dust, residues of building materials. All surfaces that will come into contact with the sealant must be clean and degreased. Only in this case will the necessary adhesion and preservation of the properties of the applied acrylic be ensured.

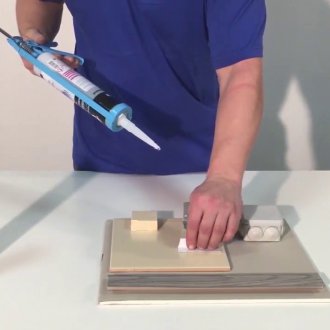

When using sealant in tubes, an assembly gun is required for operation. It is characterized by ease of use and affordable price. The gun is inserted into the tube, the “nose” is cut off and the dispenser is installed. Using a piston, the mixture is extruded uniformly. It should be applied at an angle of 45 degrees to the seam being sealed, this will provide maximum adhesion to the surface.

When using sealant packed in plastic buckets, a rubber spatula is used for application. This hand tool is practical and easy to use, it is used to seal and to remove excess. Correction of the seam is carried out until the sealant has hardened. A thin layer of dried sealant can be removed with a wet cloth.

When using waterproof or conventional acrylic sealant on objects with a large amount of work, there is a desire to save. It is possible to reduce the consumption with the help of a special sealing cord, which fits into the seam. This is true for deep gaps between the window sills and the frame, baseboard and wall, when laying large format tiles. Using this material will help reduce sealant consumption by 70-80% and speed up the process of filling voids.

One of the main advantages of this type of sealant is the possibility of their further coloring. To do this, dry the layer of waterproof sealant with sandpaper, remove dust and debris, after which you can apply acrylic or oil paint.

Sealants of white or any other color based on acrylate are environmentally friendly compounds. Water is used as a solvent, so if it gets on your hands, the sealant is easily washed off with water.

Leading manufacturers of acrylic sealants

All the positive properties of acrylate-based formulations are characteristic only for quality products.The availability of acrylic acid derivatives and their low price lead to the fact that acrylic sealants are often falsified. For this reason, it is necessary to use the products of well-known manufacturers; in our market, sealants from Poland, Germany and Russia deserve the most attention. Among the most famous manufacturers:

- Novbytkhim - a Russian company, produces acrylic sealants in compact tubes;

- Zigger - a German manufacturer that produces one-component compositions for repairing parquet and laminate, as well as tubes with white sealant for sealing joints and cracks;

- Henkel - a German company offering high-quality frost-resistant sealants in various containers;

- Belinka - a company from Slovenia that produces elastic sealants for parquet and civil works;

- Loctite - Russian frost-resistant sealant for sealing joints of sedentary structures;

- Penosil - compositions with increased adhesion, can be used to work with plastics, manufactured at Russian enterprises of an international concern;

- Tytan - practical sealants from Poland, distinguished by an excellent balance between price and quality.

It is not recommended to use cheap acrylic sealants of unknown brands, the cost can be reduced only through the use of low-quality raw materials and a large number of fillers. Such compositions have poor technical characteristics, are characterized by low viscosity and poor adhesion, and are characterized by a short service life.