Water radiators: quality and reliability are checked not only by time (22 photos)

Content

Water heating radiators have a simple principle of operation: water heated to the desired temperature is supplied through pipes from the boiler to the building. Through the heating system, water is distributed throughout the premises.

Types of water heating radiators

Products can be made in the form of sections or panels. For the production of steel, aluminum, cast iron. Design features and production technology of models made of the same material may vary.

Steel radiators

These heating devices are available in two types - panel and tubular.

Panel represent a design from several heating elements and convector fins. Such products have a low cost and good efficiency - about 75%, therefore, are in great demand.

The advantages include:

- low inertia and high heat transfer;

- small amount of coolant;

- environmental friendliness of the device, therefore, are often installed in public institutions (schools, hospitals, kindergartens);

- affordable price.

Of the minuses, we can distinguish:

- the formation of corrosion on the inner surfaces of the radiator after draining the water;

- convection leads to the spread of fine dust and can cause small drafts;

- It is not recommended to be installed in high-rise buildings, as steel radiators are very sensitive to random sharp surges in water pressure and can be destroyed.

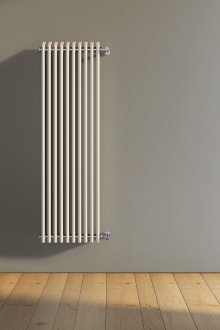

Tubular radiators look like combined steel pipes along which hot water moves. The manufacture of such structures is more expensive than panel, which affects the price.

The advantages and disadvantages of such models repeat the features of panel designs. However, some operational characteristics are higher: working pressure - 8-15 bar (for panel ones - 6-10), thermal power - 1250-1600 W, maximum degree of hot water - 110-120.

There are many design options for tubular radiators. Some manufacturers use a polymer coating to protect products from corrosion.

Aluminum Water Radiators

In the manufacture of products, two manufacturing methods are used: injection and extrusion.

In the technology of the first type, the injection molding method is used. In this case, the battery is obtained with wide channels for hot water and has strong thick walls. The system of sections allows you to add or remove elements.

In the extrusion method, the vertical parts of the structure are extruded on an aluminum alloy extruder. It turns out a whole product in which it is impossible to change the number of sections.

Advantages of aluminum radiators:

- light weight greatly facilitates the installation of the product. No special devices are required for installation work;

- high heat transfer rate provides a leading place in the ranking of batteries;

- the room warms up for a short period;

- equipping the product with a temperature controller increases its efficiency;

- water radiators look very original thanks to their modern design.

Among the shortcomings can be identified:

- modest service life - up to 15 years;

- a clean coolant is required so as not to provoke the formation of corrosion;

- water leaks in sectional models are not excluded;

- sensitivity to pressure surges of the coolant.

Performance characteristics: pressure - within 16 bar, heat capacity of one section - from 82 to 212 W, withstands hot water up to 110 ° C.

It is preferable to install aluminum radiators in rooms with an autonomous heating system. Since poor water quality in the heating system causes corrosion, water pressure surges can lead to the destruction of radiators.

Some companies use alloy in the production of radiators (silicon, zinc, titanium are added). Such materials significantly increase the operational parameters of products, but at the same time the cost of radiators increases.

Cast Iron Radiators

These models can be considered the founders of heating systems. They differ in neat appearance. As a rule, the design of heating radiators is modest. They are characterized by reliability, long service life (about 50 years), and democratic prices.

Cast Iron Benefits:

- does not give in to corrosion;

- the rooms warm up well;

- metal keeps heat for a long time, which is important for possible shutdowns of heating.

Among the shortcomings can be identified:

- it takes time to warm the walls of the radiator;

- a solid weight makes it difficult to deliver products; during installation, it is necessary to ensure their reliable fastening;

- high sensitivity to water hammer (occur when water pressure surges).

Performance indicators: operating pressure - from 9 to 12 bar, section heating capacity - up to 160 W, maximum water temperature - 110˚С.

Unusually look designs made in the style of "retro". Exquisite art casting can turn a radiator of water heating into a real decoration of the room. However, such models are very expensive.

Bimetal heating radiator

In the manufacture of such models, two metals are used. The design of the product includes a steel tubular core and an aluminum shell. Sectional and integral radiators are available.

The main advantage of monolithic models is the ability to withstand pressures up to 100 atmospheres. The design is a sturdy steel base coated with an aluminum shell.

Two types of radiators are available: with a tubular core along the entire length of the channels and batteries, where the channels are made of steel only in vertical sections. The first model is highly reliable, but you have to pay for it accordingly. The second - it costs 20 percent cheaper, it gives off heat better, but it is more prone to the formation of corrosion.

Product Advantages:

- high heat dissipation;

- ability to hold water shocks and pressure surges;

- simple installation and nice appearance;

- resistance to corrosion.

Disadvantages:

- less heat transfer compared to aluminum models;

- high price.

Apartment buildings and high-rise offices are ideally suited for the installation of such radiators.

Battery Nuances

Having decided on the material and type of radiator, it is necessary to make sure that the power of the product is enough for heating the room. This parameter depends on several factors: the size of the room, the number of external walls and window openings, the type of house (brick, panel), the material of the window frame (plastic, wooden).

If we take as a basis a room with a three-meter ceiling and window openings up to 1.5x1.8 sq.m., then we can be guided by the following figures:

- for rooms with one window, a power of 100 W / sq.m with one external wall and 120 W / sq.m with two external walls is required. If the room has two windows, then the power indicators will be 120 and 130 W / sq.m, respectively.

- if the windows of the rooms "look" to the north, northeast, then the power level should be higher by 10%.

- if the battery is installed in a deep open niche, the power indicator should be higher by 5%. And if the radiator closes a solid panel with two horizontal slots, then the parameter should be 15% more.

When there is no desire to bother, you can simply take into account that for heating 1.5-2 sq.m. The premises need one section of battery. In this case, of course, it must be borne in mind that the battery capacities of different materials also differ.

Approximate power of one section: pig-iron - 80-150 W, aluminum - 190 W, bimetal - 200 W.

Manufacturers usually indicate more accurate information in the technical specifications.

Connection of radiators

The value of the connection options should not be underestimated. It is this factor that affects the heat transfer power of any model. There are two ways to connect pipes: one-way and two-way.

- The most common order is when the pipes are connected on one side (typical for high-rise buildings). In this case, different schemes are used. If water is supplied at the top of the product, and is discharged at the bottom, then the heat transfer capacity is 97%. In the opposite case (water enters from below, and discharged from above), the power is approximately 78%.

- In the case of two-way connection, two options for the location of the pipes are used. When water is supplied through a pipe connected at the top and discharged at the bottom on the other hand, one hundred percent heat transfer is ensured. If water is supplied from below and output from above, then 20% of power is lost.

This option is most rationally used for long models, as it provides uniform heat transfer along the entire length of the radiator.

Possible lower connection of both pipes. In this case, with one-sided arrangement of pipes, power is reached within 78%, and with two-way connection - 88%. Such an eyeliner is justified when mounting structures installed under the floor.

Rules for installing radiators

The main requirement for installation of any kind is to ensure proper circulation of heated air. Therefore, during installation, the following conditions must be met:

- the distance from the window sill / bottom of the niche to the battery should be at least 10 cm. In this case, the gap from the wall to the battery should be kept at least three quarters of the radiator depth. Failure to comply with these standards will make it difficult for warm air to enter the room;

- during installation, it is important to maintain the correct level relative to the floor. When placing the battery closer to the floor than 10 cm, the outflow of warm air will deteriorate (room heating will deteriorate). If the distance is more than 15 cm, then there will be a large temperature difference below and above the room. The optimal gap between the floor and the battery is 12 cm;

- if you install a wall-mounted water radiator (not in a niche under the window, but next to it), you must fix the product no closer than 20 cm. Otherwise, air will circulate worse and dust will begin to accumulate behind the structure;

- it is not always possible to mount the battery on the wall (panoramic glazing or fragile walls). In such cases, floor radiators are installed. If possible, it is advisable to use additional wall brackets, as this will reduce the load on the floor.

Thanks to the varieties of heating systems, you can choose the model that is best suited for each room. If there are difficulties with the choice, then it is advisable to contact specialists. In order not to freeze in the cold season and not to receive surprises in the form of leaked sections, it is better to "measure seven times" before buying once.