Do-it-yourself stove-stove: design features (23 photos)

Content

A variety of modern heating systems allows you to heat any type of room. Dozens of types of boilers and stoves are effectively used for both residential and industrial premises. Despite the modernization and improvement of heating devices, there are types of stoves such as a stove potbelly stove, which, thanks to their technical characteristics, remain to this day at the stage of equipping some categories of buildings.

Advantages and differences of cast iron stoves

Modern stove stoves are several types of devices that allow you to organize heating in rooms of a small area. The stove-potbelly stove can be made of various materials, differ in design, size and principle of operation. Such heating devices are especially popular in rooms of the following type:

- in country houses;

- on garden plots;

- in small country houses;

- in household buildings;

- in bathhouses.

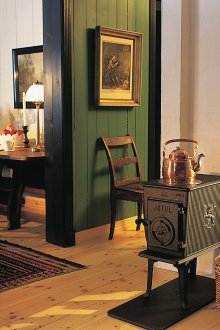

The most famous and sought-after model of such a mini-stove for heating is the cast-iron stove “potbelly stove”. Currently, the assortment of such long-burning stoves produced by both domestic and foreign manufacturers is so diverse that it allows you to choose the right “stove” not only for giving, but also for home. Thanks to new trends in the design and decor of housing, a cast-iron stove of small and medium sizes is applicable as an unusual fireplace.

The stoves of the stove in the interior fit perfectly into the popular loft style, complement the space, provide coziness and a comfortable stay in the room. Use this design as a fireplace, but you must first calculate the total area of the room where you plan to install.

The optimal size of the room, in which such an impromptu fireplace will cope not only with the decorative, but also with the heating task, is an area of 55 to 65 square meters. It is much better if the mini-fireplace is installed in the center of one of the walls, where there are no window openings. It is permissible to paint metal stoves of potbelly stoves, complement them with suitable decorative elements.

It is recommended to enclose such a home fireplace with an ordinary building brick along the back and each of the side walls of the structure. Brick laying should not be done close to the surface of the stove, leaving a free gap of 12-15 cm. Having thought about erecting a small fireplace within your own home, each owner must remember that the use of “bourgeois” is convenient in that they are mobile and can be moved around in place if necessary. But cast iron structures can only serve as a good basis for fireplace objects, excluding the possibility of their own making.

Making homemade "bourgeois" horizontal type

A home-made stove is usually made on the basis of a used gas cylinder. A gas cylinder stove-stove is the best option for a heating mini-device for garden houses and small household premises.There are two options for a homemade design, depending on the location of the container:

- vertical

- horizontal.

With any method of manufacturing "bourgeois" of long burning, you must take care of your safety and take all fire precautions. To do this, it is not enough to remove the remaining gas from the cylinder; it is necessary to rinse the inside of the container with clean water. Such manipulations will ensure the safety of the use of used containers and completely clear the cylinder from the inside. Considering the horizontal location of the stove, it is worth considering what the device will be heated in the future. If for housing you need a stove for a wood stove, then placing the cylinder horizontally, we will get an ideal device for heating, not inferior to powerful factory boilers.

In addition, horizontal type woodburning stoves can be used not only for heating rooms, but also for cooking and heating food. After cleaning and rinsing the balloon, you can begin to work directly on the creation of the furnace. There are a lot of ways to produce a home-made “potbelly stove”, but it is recommended to adhere to the following algorithm of actions:

- Cut the top of the container with a grinder or other suitable tool.

- Fixing (welding) of reinforcing pieces in the inner cylinder space.

- Marking of the furnace compartment, cutting at the bottom of the cylinder of a rectangular hole, which further performs the function of the entrance.

- Drilling several holes in the bottom of the furnace billet in order to remove excessive accumulations of ash.

- Determine the desired height of the structure. With this in mind, measure the “potbelly stove” legs that are suitable along the length and weld them to the bottom.

- Provide the top of the workpiece with a chimney. The element is welded to a pre-cut hole.

In the case when a potbelly stove with a hob is made, a metal frame that is most suitable in size is additionally welded at the top of the container. Such a stove-stove with a burner perfectly copes with the tasks of heating the air and cooking, not only in the country, but also in other buildings without central heating, for example, in warehouses, garages and utility rooms.

Features of vertical homemade stoves

A stove for a summer house made of gas cylinders according to the vertical principle is different in that it takes up much less space than a home-made horizontal heating design. Most craftsmen prefer to make the furnace according to this scheme, since it is much simpler than its counterparts:

- Marking the desired location of the ash pan and door.

- Installing suitable dampers on slots.

- Measure 10 cm from the entrance to the furnace and weld several reinforcing grates at the indicated level.

- Welding the legs to the bottom of the device.

- For the chimney, side holes are drilled to which a metal tube is welded.

The upper surface of such a stove is relatively small, so it is quite difficult to combine such a design with a stove. For these purposes, the furnace billet should be placed horizontally. The main advantage of the vertical design, in addition to small dimensions, is the rapid heating of the air. The vertical stove type country stove is often used to heat country houses after the winter period or to increase the air temperature in production rooms with negative temperatures.

The ability to make a furnace with a water circuit yourself

What is the need to make such a stove yourself? In fact, such devices are quite expensive in price and, accordingly, are not available to all customers. And the need for such a furnace is great for most of the population. That is why, using the experience of experienced craftsmen and home craftsmen, you can quite successfully make such a "potbelly stove" with your own hands.

A waterburner stove with a water circuit is an ideal heat source in the absence of central heating. This water heating design has a number of advantages:

- high performance indicators. The cost of a home-made device is several times lower than factory stoves, and when using waste material as a basis, it is completely zero;

- the furnace operates regardless of the fuel being poured. It is permissible to use coal, peat, firewood, vegetable waste;

- the autonomous nature of the operation of the stove, since the design is absolutely not connected with any source of electricity.

The kiln stove system operates in accordance with the principle of natural circulation. Heat comes from the carrier and is distributed throughout the internal space of the device. During the combustion of fuel materials, the potbelly stove does not need additional energy sources, including electricity.

In order for the contour potbelly stove to please with its work, it is necessary to observe a certain phasing in actions:

- the choice of material from which the stove will be made, and the desired shape of the device;

- manufacture of the base case of the potbelly stove. The basis is most often taken either as a pipe with a diameter of about 300 mm, or a metal sheet of 5 mm in thickness;

- "Open" the metal or pipe. Schematic drawing of all planned holes, bends and welds;

- manufacture of a heat exchanger, its installation and connection to a common heating system;

- installation of working radiators.

The contour potbelly stove consists of an expansion tank, pipes, an internal heat exchanger and built-in radiators. As a result of which, due to the multicomponent design, it is necessary to take care of the reliability of fastening of elements and the quality factor of all welds. Reliable joints eliminate the possibility of leakage in one of the parts of the structure.

Water contour "stoves" are heated by the movement of water, starting in the internal heat exchanger, entering the pipes, and then into the radiators, where heat is transferred to the outer space. The cooled water again enters the heat exchanger.