Stone fence: features and benefits (25 photos)

Content

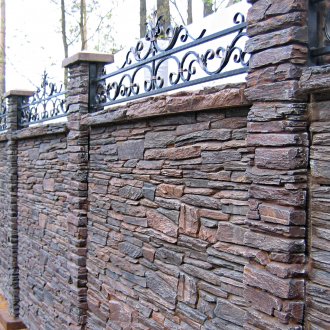

The fence for the house is a kind of calling card of its owners. It is in the appearance of the fence that the first impression is formed of how practical the owner of the house is and is fundamental. Without a doubt, the owners of stone fences would always be in the first place, despite its obvious laboriousness and cost. What are the advantages of stone fences?

Stone fence - seriously and for a long time

The main advantage of a stone fence is its unlimited service life. For example, you can recall the ancient buildings of stone, well preserved to this day. Others did not succumb even to explosions. We list the remaining advantages of laying a stone fence:

- a stone fence will fit any architectural style of the building;

- since stone is a natural material, the fence from it will look natural and organic anywhere: whether it is a fence for a summer house, for a house in a village or in a city;

- natural stone fence is environmentally friendly and safe;

- a solid wall of stone will be a reliable protection against fire in case of fire;

- installation of such a fence is simple, despite the complexity;

- the ability to combine different types of stone and other materials will create an architectural masterpiece from the fence;

- a fence made of stone can be either continuous or with gaps;

- a solid stone fence, coupled with a deep foundation, will create a reliable barrier from thickets if the territory behind the fence is not ennobled.

Brick or stone fences do require a solid foundation. Only in this case, the construction will last a long time.

Stone fence foundation

Before starting work on the foundation, it is necessary to carefully plan everything on the ground and draw a sketch. Then clear and level the territory and mark it with rods and ropes around the perimeter. The foundation for such a heavy construction should be continuous tape and necessarily reinforced. Its construction standards are approximately the following:

- 15 cm wider than the finished structure;

- the height of the cap, that is, the part protruding above the ground, at least 10-15 cm;

- the depth on complex soils (heaving, flooded) is not higher than the average freezing depth in your area.

Next, you need to dig a trench along the markings. Fill the bottom with a 5-cm layer of sand and carefully compact. Install formwork. Any suitable improvised materials are suitable for her: boards, plywood. After that, on a sand cushion, you need to lay the frame from the reinforcement. For this type of structures, 8 mm rods are quite suitable. In total, two layers of reinforcing frames are needed. The second layer is laid 50 cm below the surface. For greater strength, these two layers are reinforced with vertically driven rods. At the same time, pipes are installed for the pillar frame. After installing the reinforcement, the trench is poured with concrete.

For the foundation to gain the necessary strength, it must dry slowly. To do this, they cover him with wet burlap, which is regularly moistened in hot and windy weather. Formwork can be removed no earlier than two weeks later. After another two weeks, you can proceed to the next step - the installation of poles.

Stone fence posts

It is most convenient to build pillars using the sliding formwork method. First, a formwork is mounted around the frame pipe in the form of a box with a side of about 30 or 40 cm. Then, a carefully selected layer of stone is laid in it. It is desirable to place them as densely as possible to the walls of the formwork. Then the stones must be removed and laid again with the solution, trying not to leave voids. Next, we also fill in another row and leave for hardening.

A day after pouring the first tier, the formwork is carefully removed and moved to the third, leaving the second for support. Thus gradually bring the height of the column to the planned. Each time, removing the formwork, all the cracks between the stones are closed with a thick solution. Subsequently, you will need to complete the jointing.

Craftsmen can lay out extreme stones in the form of ornaments - decorative pillars for the fence will look beautiful and original.

Span manufacturing options

So, the foundation and pillars are ready, the solution is completely seized and dried out. It's time to proceed to the next stage - laying out spans. They can be not only stone. The trained eye of the designer or homeowner will imagine in advance what the whole landscape will look like with spans from other, suitable in style or contrasting materials. We offer the most popular options.

- Forged from metal. Forged openwork in the spans will look even more impressive if elements with forging are provided in the design of the house and the site. For example, a gate, gate, elements of decoration of a gazebo, visor.

- Tree. The fence made of stone and wood always looks stylish.

- Decking. This option is much cheaper and easier to install. Relieves the burden on the foundation. In addition to the usual, there are options for imitating stone, wood, brickwork.

- Facing the fence with natural stone. The span can be made of concrete and facing material. The cladding may be stone, brick, tile or panels.

Let us consider in more detail the technology of manufacturing spans of stone.

Laying out spans

This step is performed in the following sequence:

- Using reinforcement and ropes on both sides, we make guides to limit the masonry in width.

- We apply cement mortar to the foundation foundation.

- We spread stones at the edges, in the middle we fill in all the cracks with mortar and substandard stones.

- We bring the series to the end, in the process using dressing.

- Let dry for at least a day.

- Spread the next row.

In the process, do not allow the solution to hit the outer surface of the stone. The last operation will be the stitching. It should be carried out 3-4 hours after the end of work. After embedding, the fence must be washed with a brush, a foam sponge and hydrochloric acid solution. When working with acid, you must observe safety precautions: use rubber gloves and safety glasses. So that moisture does not accumulate on the top of the fence, you can install special caps. Caps can be decorative.

As we see, the laying of the stone fence is uncomplicated, although laborious. The complexity of the work can be brightened up by introducing elements of creativity into it: laying out ornaments from stones or picking up stones of certain colors. You can also use colored pigments for the solution in order to mask or, conversely, emphasize the natural beauty of the stone.

Stone fence without mortar

A solution for this type of fence will still be needed - for the foundation. And then the whole mass of stones is placed in mesh boxes. So it is called - a fence of stones in a grid or a fence of gabions.

When choosing a fence of this type, you need to remember that the size of the stones should be larger than the holes in the grid. Usually large stones of a beautiful shape are placed near the grid, the middle is covered with the remaining ones.

Fences from gabions can look unusually aesthetically and highly artistic, if during the laying of stones alternate different colors, creating patterns or creating unusual shapes from the gabions themselves: columns, semicircles, waves.

What stone can be used for the fence?

Almost any natural stone. The main thing is that it does not collapse from the action of water and looks beautiful. Most often choose:

- rubble stone fence, also known as "rock". It can be white, black, yellow or blue and their shades. Depending on the type, rubble stone is divided into flagstone, bedded, wild or ragged stone. A fence made of wild or ragged stone always has its own unique pattern and looks beautiful.

- fence made of french stone or artificial. French stone is called hollow cinder blocks made by vibropressing. Then cinder blocks are treated with special moisture-resistant compounds. The artificial stone fence has the appearance of a natural one and has a number of advantages: a variety of colors, lower weight, and standard size.

- brick fence. The technology of working with bricks has long been worked out and does not need a separate description. Has no less strength and neat appearance.

Using natural materials, you can create a durable building with a unique appearance and excellent characteristics. The main thing is that it is possible to do it yourself.