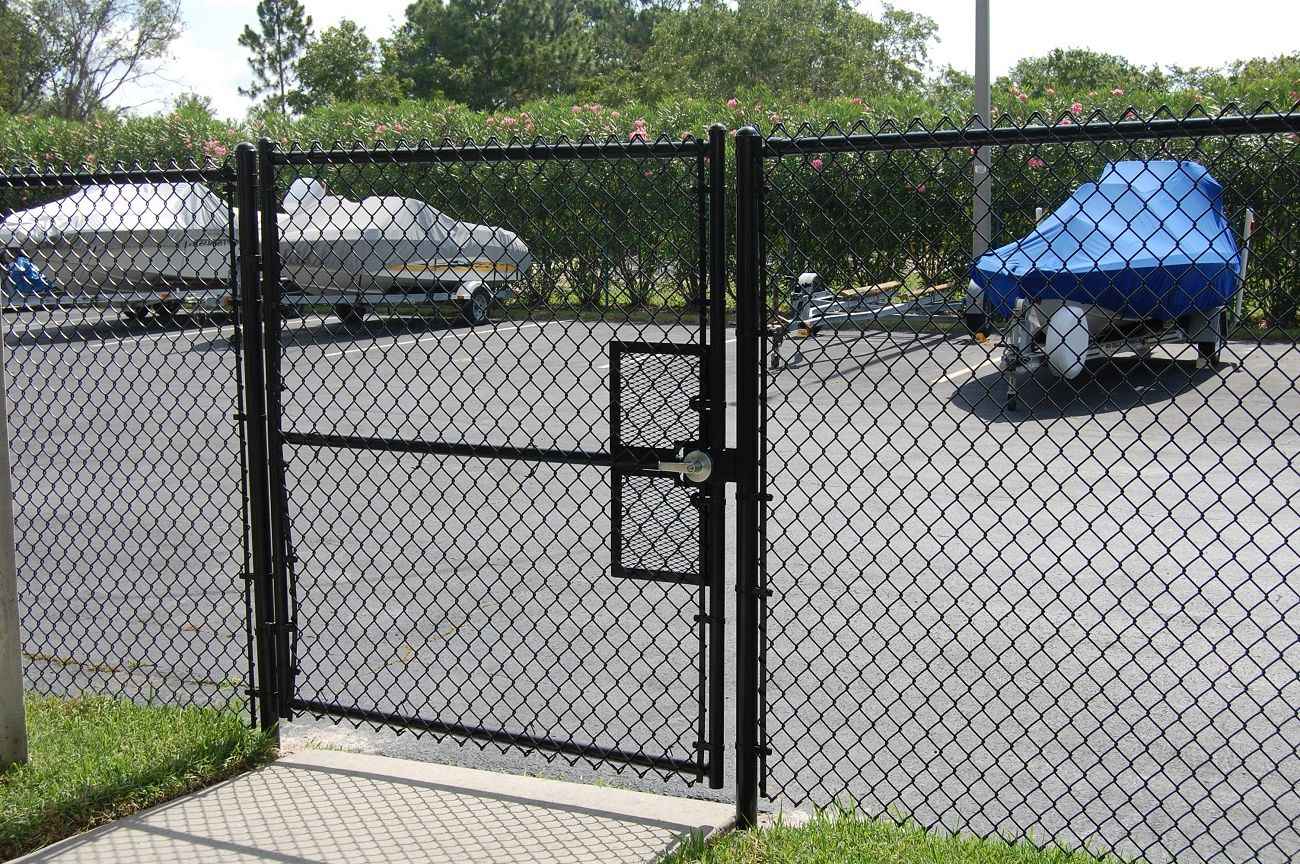

Gate from the netting: simple and reliable design (21 photos)

Content

The mesh netting is made on a special machine from steel wire. In the manufacturing process, wire spirals are screwed into each other. As a result, a web with diamond-shaped (acute angle of 60 °) or square cell shapes is formed. If the grid is assembled on a simple machine, then the ends of the wire do not bend. When using special mesh-braiding machines, the ends of each spiral are bent, which increases the service life of the product.

Types of netting

Three types of mesh are presented on the construction market: galvanized, with a polymer coating, simple (without any additional layers).

It is clear that ordinary chain-link is in no way protected from the effects of weather conditions, therefore, only galvanized sheet or coated is used to design barriers.

According to the method of creating cells, two types of mesh are distinguished:

- wicker - is formed by bending and twisting the wire;

- welded - the method of spot welding is applied.

When choosing a material, it is worth considering that wicker chain-link has more reliability. The price of the product is determined by the size of the cell - the smaller it is, the more expensive the canvas.

Polymer mesh

The wire is coated with a layer of PVC, mainly green. Recently, various options for shades of plastic have appeared. The material is sold in ten-meter rolls, the height of which is 1.2-2 m. Products with a mesh size of 35 to 60 mm are offered. It is possible to order a canvas with a larger side of the elements. For the production of chain-link wire is used with a thickness of 2.2 to 3 mm.

Advantages of polymer coated mesh:

- the absence of welded joints increases the strength of the canvas;

- Excellent adhesive characteristics of the plastic ensure the resistance of the wire to temperature and humidity. A reliable coating does not fade under the influence of ultraviolet radiation and perfectly tolerates frost up to 35 degrees.

Disadvantages: damage to the protective coating reduces the positive qualities of the wire.

In case of rupture of the polymer layer, it is necessary to cover the “bare” area with paint, otherwise water will fall into the slot and the metal under the plastic will quickly rust. The quality of the PVC layer is easy to determine visually. To do this, it is enough to consider the inner surface of the spiral. If there are scratches or cuts on the polymer, this means poor quality of the protective layer. Such a coating will burst in the winter in two to three years and will fade in the summer.

Galvanized sheet

This type of chain link is the most sought after. Due to its excellent performance, this material is suitable both for temporary fencing of plots, and for creating inexpensive permanent fences and gates in the country.

A web is produced with the following characteristics: cells are produced with a side of 10 to 100 mm, the wire is used with a thickness of 1.2 to 6.5 mm, the web can have a height of 1 to 3 m.

Gates and gates from the netting net

Despite the flexibility of the canvas, the grid is suitable not only for enclosing areas, but also for decorating gates and gates. Moreover, thanks to simple methods of assembling the elements, it is possible to build completely functional structures from the netting with your own hands to organize the passage / passage to the site.

The advantages of a mesh door:

- speed, strength and reliability of the installation;

- low price of materials, ease of transportation and the availability of self-assembly of the structure;

- light weight and does not block sunlight;

- resistance to mechanical damage, temperature and humidity;

- long service life, the ability to repair cut sections without dismantling the structure;

- ease of maintenance.

The disadvantages include a modest appearance, the accessibility of the site for viewing from the outside, the need for periodic painting of the entire structure.

The grid is also good because it is suitable for designing not only simple swing gates, but also looks quite organically in sliding or sliding structures. So the lack of space can not be considered an obstacle to the construction of structures.

In order for the gate and gate from the chain-link to turn out reliable and last for a long time, you need to use high-quality material and make accurate calculations and measurements.

For the manufacture of the construction, the following components will be needed:

- Rabitz. A galvanized sheet with a cell side of 50 mm is preferred. When choosing a roll height, they are repelled from the door parameters. Since the structure does not intend to close the site from outside views, a blade approximately 1-1.5 m high is suitable. The optimal width for the gate is 3-3.5 m.

- pipes for supports and frame. Metal products can be considered a universal material (pre-primed and painted). Wood is rarely used as a support, as it is not resistant to humidity and temperature extremes. To use brick is expensive and time-consuming (the foundation is necessarily laid out);

- tension wire. Suitable galvanized wire with a thickness of more than 2 mm.

Since the net does not give the gate any sail, there is no need for a reinforced frame. However, one must take into account the softness of the canvas and the possibility of its sagging over time, so it is advisable to install additional crossbars (diagonal and at the location of the castle).

Work stages

Swing gates from the netting have a simple device and can be installed during the day, subject to preliminary drawing up a diagram and drawing of the gate from the net.

- Structural elements of appropriate sizes are cut from pipes.

- Metal parts are polished, the places of cuts are carefully processed.

- Billets are welded according to the drawing. In order for the frame to have the correct shapes, it is recommended that you first conduct spot welding. After taking measurements of all the elements and angles, you can make a continuous weld. Welding areas are ground.

- Hinges and a locking device are welded onto the frame. You can install a simple deadbolt on the gate - this will be quite enough. So that when welding the elements do not lead, it is desirable to first fix them with self-tapping screws. The entire product is coated (primed) with an anti-corrosion compound and stained.

- The desired piece of chain link is prepared. The dimensions of the canvas should correspond to the internal parameters of the frame. To separate the grid section, you just need to unscrew one wire in the right place.

- To attach the canvas to the structure, you can apply two methods: fix the grid to the hooks welded to the frame, or use a tension wire. When applying the latter option, it is necessary to stretch the wire through the cells of the chain-link and weld to the gate (lower, upper parts of the frame and the diagonal crossbeam). If there are no additional elements, then the tension wire is simply pulled through the middle of the web.

- Set the pillars. In order for the gates from the netting net to be stable, the supports are dug to a depth of 1 m. The best option is half the height of the gate. Pillars are fixed in different ways: they simply clog (solid soil) or concrete in the ground (loose soil).

- The made gate leaves are hung on the supporting posts.

To ensure a long service life, the distance between the ground and the lower parts of the wings should be at least 10 cm.

In order to assemble and install the gate from the net of the netting with your own hands, the above steps are repeated.

Recommendations for installing gates from the netting

The mesh cloth should be stretched not only tightly, but also without distortions.

Before you install the poles, it is important to make sure that they are strictly upright. Otherwise, the entire structure is quickly distorted during operation.

If the site is located near the road, the carriageway, the gate leaves and gates should open inward so as not to interfere with the movement of vehicles.

In the case of temporary installation of gates from the netting in the country, it must be borne in mind that the canvas can be used for various other purposes after dismantling the structure.

When installing the gate and fence from the netting, you can use nets with cells of different sizes.

Proper installation of the gate will ensure a long service life of the structure. If you show imagination, then on the grid you can weave an interesting pattern or ornament that will give the gate an individuality and originality.