How to make a greenhouse from cellular polycarbonate? (22 photos)

Content

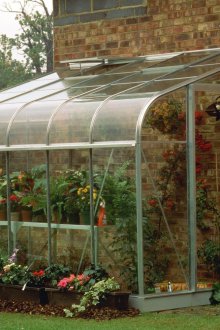

It is not surprising that lightweight building material is used for the manufacture of greenhouses - cellular polycarbonate, sold in sheets, so the design of greenhouse structures can have different parameters and shapes. Their basis is necessarily a strong frame, which is made of profiled steel pipe with a cross section of 20x20 mm. A metal or aluminum profile with corrosion protection can also be used. Sheathed frame with sheets, the optimum thickness of which is 4-6 mm. Compared with glass, the material is flexible, simple and easy to use, there is no fragility.

Features of cellular greenhouses

The main requirement for greenhouses made of polycarbonate is the presence of good ventilation in hot weather. This is necessary so that the lining does not overheat, since under the influence of high temperature the geometry of the cellular sheets will change. To avoid increasing or decreasing the size of the casing, it is best to install in late autumn or early spring. Deformations occur when the sheet is enlarged, and cracks form when their parameters decrease. The optimum air temperature for installation work is + 10 ° C degrees.

The greenhouses made at the plant differ in parameters, shapes and constructional solutions. However, not everyone can afford to buy such a structure, and then a bold decision comes - "do it yourself." What size a mini-greenhouse should have depends on the area of the garden plot and the planned number of plants to be planted. Garden structures in the lightweight version have become indispensable in personal plots, because several dozen beds will be protected from the weather and cold, which means that you can get an early crop.

Varieties

For growing seedlings, herbs or seasonings in small quantities, small ground-type greenhouse constructions are suitable, which can easily be lifted and moved to the right place, so that there are no problems when planting plants in the ground. If there is a lot of seedlings, or it has high stems, then the design should be buried, while the optimal parameters should be observed, which should not exceed 150 cm in width and height. The length can be any, as far as the site and personal desire allow.

When creating a polycarbonate greenhouse with an opening roof, three simple and convenient models can be used:

- Single slope;

- Gable;

- Arched greenhouse snail.

Regardless of the geometric shape, a polycarbonate greenhouse with an opening top is convenient and practical. Such a garden structure requires the correct calculation of materials and is carried out on the basis of a previously drawn up technical drawing. The most practical way to select parameters is the dimensions of the mesh sheet, the width of which varies from 600 to 2100 mm.

In order not to have a lot of waste leading to unnecessary costs, the design should be designed taking into account the parameters of the sheet.

The presence of an opening roof allows you to adjust the temperature inside the structure, which eliminates the overheating of not only plants, but also polycarbonate sheets. The technology for creating greenhouse structures depends on the shape and design features of the upper part of the structure intended for opening. There are several common types of hotbeds, and making them yourself will not be difficult at all.

Rectangular model with a pitched and gable roof

To create a greenhouse made of polycarbonate with an opening top, you must first assemble the frame.

The simplest and cheapest models include a single-pitched roof, which is a regular box, which is sheathed with cellular material on four sides, and the upper opening part is inclined. The main disadvantage of this design is the slight slope of the rising roof, which creates inconvenience during operation and there are negative aspects for plants. With insufficient slope, the snow lingers, so the top needs to be cleaned independently. And the plants do not receive enough sunlight, which affects their activity and development.

The single-slope option is suitable for a small-sized greenhouse, because only in this case the movable frame for the upper part can turn out to be reliable and durable. With an increase in size, you will have to use thicker sheets that transmit light worse.

More convenient to use is the gable version of the greenhouse, which is a mini-greenhouse of small dimensions. The gable roof has a sufficient slope and therefore copes well with mechanical loads. This is ideal for creating buried greenhouses. This design allows you to grow undersized and tall crops.

No matter how accurate the installation of the moving top is, the natural ventilation, which is so necessary for greenhouse constructions, will necessarily be present. At a price, the gable model is much more expensive than the gable model, but if you install the structure yourself, then the greenhouse will be cheaper. You can make the opening top on one or both sides, the second option will affect the cost of construction.

Cellular polycarbonate is attached to the frame using special screws.

Arched shell model

Open-top snail greenhouses are common options for the manufacture of which flexible hollow-cell polycarbonate is required. The semicircular arch of the “shell” greenhouse is not affected by condensate. The accumulated moisture leaves the walls and does not affect the planted crops. The height of the arched mini greenhouse should correspond to the varieties of plants that it is planned to grow in it.

This model can be of two types:

- The lower part is in the form of a box, the upper part is an arched roof, movable on one or two sides.

- Without a box with arched sidewalls to the very bottom with one-sided or two-sided opening.

The arcs are bent out of the profile pipe using a special tool. All prepared elements for the bottom (frame) and top are connected by welding. It is necessary to decide in advance which side parts will be raised in order to equip them with axial bars previously cut at an angle of 45 degrees. To ensure the mobility of the upper part, hinges are installed.

Completely made construction is installed on the prepared foundation. The disadvantage is the low height, which does not allow to plant tall plants.

The greenhouse design with an arched roof is simple, so everyone can cope with its manufacture.

Foundation creation

Before installing a greenhouse made of cellular polycarbonate, it is necessary to build a foundation:

- According to the size of the greenhouse, a trench 10–25 cm deep is excavated in the area.

- The bottom is covered with sand (about 1/3 part) and compacted.

- For the foundation, brick, concrete with the use of formwork is used or a ready-made box of wooden timber treated with an antiseptic is installed.

- The remaining space in the trench is covered with gravel and compacted.

At the last stage, the frame of the greenhouse is installed. As fasteners, long metal pins or self-tapping screws are used.

The location of the greenhouse on the site

Before installing the foundation, you should correctly choose the location of the mini-greenhouse made of polycarbonate. The structure should be in such a position that the sun is present throughout the day. If the site is small, and it is difficult to find such a place, then it is worthwhile to tentatively arrange the structure and beds in the greenhouse from west to east.

Advantages and disadvantages

They seek to acquire a garden mini-greenhouse for the sole purpose of providing the best conditions for growing plants. Such a simple structure helps to get an early harvest, and also to serve vegetables and berries on the table out of season. When using cellular material, structures have a number of indisputable advantages:

- It retains heat well inside;

- A sufficient stream of light arrives;

- Strong casing is able to withstand heavy loads created by snowdrifts, as well as shocks from shallow hail;

- High aesthetics;

- Efficiency and practicality when using a certain area for planting plants and seedlings;

- Convenience in service.

- Small parameters that allow mounting in small areas;

- Easy installation - one person can handle it.

Among the shortcomings, only a short service life can be distinguished, which completely depends on the correct installation. If the fastenings of the cellular sheets and the requirements for the installation of the structure are not violated, then there will be no shortcomings, and the light structure will last for a dozen years. Knowing how to make a greenhouse out of polycarbonate, it will be possible to grow early varieties of vegetables, dill, parsley, lettuce, lettuce, sorrel, and onions in hidden beds from the weather. When installing trellis inside the structure, you can get early strawberries and strawberries. The optimal dimensions of the structure are in length from 200 to 300 cm - gable, from 150 to 400 cm - gable.