Advantages and areas of application of Green board panels (21 photos)

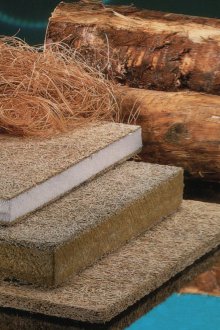

Among the various materials for the construction of low-rise houses, Green board fiberboard is deserving of attention and praise from construction companies. Their production is based on the use of a pressed and hardened mixture consisting of Portland cement, water glass and wood wool, which is a fiber of deciduous and coniferous trees, up to 25 cm long. Green board panels are environmentally friendly innovative materials and confidently occupy their niche in areas of industrial low-rise housing construction. In terms of bending and compression strength are unparalleled.

Benefits

Innovative building material combines excellent performance and low cost. Greenboard panels have several advantages. Their list includes:

- compliance with international quality standards, environmental and fire safety, sanitary rules and norms;

- strength, elasticity of structure and identity to wood;

- the ability to produce sip panels based on fiberboard;

- long service life of the material exceeding a century;

- ease of installation during the construction of the outer walls of a low-rise building and the cost-effectiveness of fastening;

- ease of processing;

- low weight of panels, practicality, reliability;

- high strength of the material, allowing it to withstand heavy loads;

- resistance to corrosion, open flame, aggressive chemical environments, spores of pathogenic microorganisms of the fungus, mold;

- lack of risk of wall deformation during the construction of a house in regions characterized by low temperature and high humidity;

- excellent heat and sound insulation properties;

- reasonable price of fiberboard panels.

The innovative building material does not contain harmful components and formaldehyde, the concentration of which in OSB boards varies between 6-10 mg per 100 g of material. The use of Green board fiberboard panels allows to increase the degree of earthquake resistance of buildings.

Fields of application

The universal operational characteristics of a building material based on wood wool have predetermined the ability to build high-quality, comfortable, cozy houses and other construction projects in any climatic zone of the country and beyond. Fields of application for Green board fiberboard are:

- the construction of load-bearing structures in frame housing construction;

- sheathing of external wall surfaces, partitions, roofs, ceilings, attics, basements in order to ensure a high level of sound absorption, noise and heat insulation;

- arrangement of fixed formwork using heavy concrete;

- creation of protective shields necessary to reduce the noise level near railways and highways;

- installation of suspended ceilings, combining a high level of sound absorption and design ideas to create an original interior in rooms;

- production of environmentally friendly sip panels;

- ensuring fire safety of industrial buildings, industrial structures;

- ground floor insulation.

For the finish of fiberboard used for insulation of external wall surfaces, it is allowed to perform facade brick and stone cladding, siding, plastering with subsequent painting. To finish rough repair work indoors, it is recommended to use wall plastering with clay-based solutions.

The use of fiberboard for the installation of partitions provides the opportunity to erect structures up to 3 m high and 3-4 m long without using frame piers. Alabaster (gypsum) mortars, which contain 20-30% of lime, are recommended for joining Green board plates. Laying fiberboard building material on the base of the roof of the house provides the opportunity to prepare the surface for the installation of roofing materials, including their rolled surfaced varieties.

Criteria for choosing fiberboard

In the building materials market, various grades of fiberboard can be purchased: GB1, GB2, GB 3, GB450, GB600, GB1050, which differ in a number of operational characteristics. The criteria for their selection include:

- scope: external or internal works;

- thickness, indicators of density, humidity, swelling, water absorption;

- bending and compression strength;

- modulus of elasticity, coefficient of thermal conductivity and vapor permeability;

- hardness and specific heat;

- product price.

Given these distinctive characteristics of the material, you can always choose the best type of Green board for outdoor, interior decoration, wall insulation, roofing, and premises.

Production stages

The construction of a low-rise building made of panels based on Green board is a rational and cost-effective solution that combines environmental cleanliness, fire safety, excellent performance. The manufacturer of building fiberboard with a high degree of environmental cleanliness is the company "Building Innovation". Production began in 2007 at a factory built on an area of 35 hectares in the Vladimir region. The stages of the production of Green board from hardwood and coniferous wood include:

- delivery of timber and its unloading to the site with a hard fire coating;

- sorting of raw materials by length, thickness, species and purpose on a special line for the single issue of logs with an automated control system;

- feeding the sorted raw material by the loader to the receiver of the debarker or to the drive for storage;

- removal of curvature, knots, other defects on rejected logs;

- removal of bark and cutting into 2-meter blanks with their subsequent sorting and storage to even out the moisture content of wood for the spring-summer period;

- cut into blanks, 0.5 meters long and their subsequent laying in metal containers;

- planing wood into fibers 25 cm long, 1-3 mm thick;

- wetting and mineralization of wood wool, subsequent shipment on the line of white and gray cement;

- mixing the components of the fibrolite mixture in the mixer, controlled by an electronic dosing system;

- uniform distribution of the mixture on pallets, sealing of the edges, cutting and pressing plates to a predetermined thickness on hydraulic presses, fixing and primary hydration in special forms;

- automatic disassembly of pallets and secondary hydration;

- drying, grinding, edge trimming, trimming and painting of plates.

High-tech equipment for painting innovative material by spraying allows you to get high-quality coating of plates for finishing ceilings and walls in rooms. Painted products after drying in chambers are collected in piles and sent to the packaging workshop.

The use of Green board makes affordable, environmentally friendly, comfortable, safe, energy-efficient housing accessible for the population.Buy high quality building material and make your construction dreams come true!