Metal siding: types, installation features and application of the material (21 photos)

Content

The appearance of such material as siding is associated with the introduction of frame-panel construction technology for buildings. This method of building structures is considered quite fast.

Features of metal siding

Siding (cladding panels) are made of various materials. However, the most popular type was metal options. Which siding is better is difficult to judge, since they are all completely different. Wood, vinyl, metal have dissimilar characteristics.

Metal siding structure

Metal siding is quite complex in structure. The material consists of several layers:

- The middle layer is usually made of galvanized steel or aluminum.

- Around it is a passivated layer.

- The next is the ground.

- The front side of the material is coated with either paint or polymer coating.

- The reverse side during production is covered with a protective pigment substance, which is applied using powder spraying technology.

The polymer may be any of the following materials:

- acrylic;

- polyester;

- polyvinyl chloride;

- polyvinylidene fluoride.

A polymer layer is necessary to protect the surface of the facade siding from harmful ultraviolet radiation.

Upon release, the plates are covered with a protective film to ensure safety during transportation. The size of the panels can be from 4 to 7 meters.

The siding design is equipped with an edge and a lock to ensure a secure fit. The plates are attached to the supporting structure by using special cutouts. At the ends of the products, recesses are provided for overlapping joints. The lower edges of the plates are needed to reduce humidity and provide ventilation.

The main types of metal siding

Manufacturers offer the following types of metal material in the building materials market:

- aluminum siding;

- steel (galvanized).

Installation of metal siding made of aluminum is used infrequently, since the material is quite expensive. It is usually used for the exterior walls of shopping centers or other public buildings.

Decorating a house with metal siding is used much more often than aluminum. It has the following varieties:

- shipboard;

- block house;

- corrugated board vertical;

- herringbone (double and single).

When buying this type of siding, you need to consider the following points:

- the thickness of the metal plate;

- type of external coating;

- the presence of surface defects. Even a barely noticeable scratch can cause corrosion;

- installation of metal siding.

The material is washed with the help of a pressure of water from a garden hose.

Types of metal siding are selected according to financial capabilities, climate zone and installation options.

Varieties of decorative material

Various types of metal siding can be used to create an attractive facade:

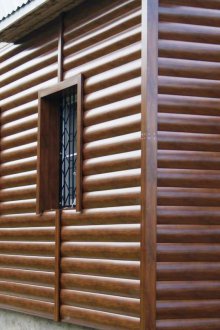

- under the log;

- under the tree;

- under the stone;

- under the brick.

All of them are diverse and spectacular.

One of the most common options is metal wood siding. It perfectly imitates various types of wood, but at the same time it has many advantages over natural layers.

To create the effect of a wooden log house, a metal block house siding is ideal. This type of material is used for facade work. Metal siding under a log is produced not only in various shades, but also with different widths of simulated logs. The material is quite resistant to mechanical damage and the effects of weather.

A siding for a block house, with log tinting, is most often used for cladding private houses and summer cottages, but in this case it is better to use a warmed blockhouse for facade cladding.

Metal siding “shipboard” can be used in climatic zones with a large amount of precipitation. This is made possible by a unique design: on each panel are two overhanging waves of each other. This creates the effect of a shipboard. A peculiar appearance contributes to better sanitation.

Metal base siding with insulation - sufficiently strong layers that belong to the category of ventilated facades. It is important to consider that no matter how durable it is, the base metal siding is installed on the frame.

Metal siding for timber with insulation or brick can be used not only for external facades, but also for the design of the inner surface of balconies and verandas. Metal cladding creates an unusual interior.

Brick metal siding is the most effective version of affordable house cladding. It imitates real building material and does not require skills for laying brick walls. The metal siding under the stone imitates the natural raw material, which is often used to create a beautiful facade. The choice is up to the customer.

Advantages and disadvantages of the material

When choosing a material for cladding, it is necessary to take into account all the pros and cons of metal siding. The main advantages of the material are:

- resistance to temperature changes;

- relatively light weight;

- ease of installation;

- high degree of corrosion resistance;

- resistance to mechanical damage;

- attractive appearance (especially metal siding under a brick or wood);

- environmental friendliness;

- long term of operation.

Along with the advantages of facade siding, there are also disadvantages:

- large dimensions are not too convenient for transportation;

- when dents appear, it is quite difficult to restore the original appearance;

- lack of thermal insulation;

- low degree of sound insulation.

Nevertheless, the advantages of the material are much greater, so it is widely used in the construction of residential and commercial buildings.

Which siding is best, everyone decides based on needs. However, in most cases, a metal-based option is used.

The use of siding in construction

Attractive appearance under various natural materials and ease of installation allow using siding not only as a cladding on the outside and inside. Metal siding under a log or other material is also good as an independent element of a building or structure in the construction of various objects:

- Warehouses.

- Supermarkets

- Terminals at airports or at customs points.

- Logistic centers.

- Objects of entertainment industry and catering.

- Gas stations, paint centers and service stations.

External material, it is used for residential buildings: private houses, country houses, outbuildings.

Mounting Features

Installation of metal siding requires the use of a large number of various additional elements:

- strips;

- platbands;

- corners;

- racks.

If the building has prepared smooth walls, and there is no need for insulation, the material is attached directly to the wall.In other cases, a supporting frame made of wood, a metal profile or galvanized metal is required.

Work sequence

Installation of metal siding consists of several stages, the most difficult of which is the installation of a leveling frame.

In order to qualitatively clad a building, the sequence of work should be taken into account:

- It all starts with the arrangement of vapor barrier. To do this, it is necessary to mount a vapor barrier film that prevents the penetration of air and steam from the room and moisture from the street.

- After this, it is necessary to install the crate - the supporting element of the steel surface. It is mounted in the corners of the building, then the perimeters of windows and doors are formed, and then - on the walls.

- The next step is to insulate the walls of the building, for this, foam, fiberglass and mineral wool are best suited. The use of insulation materials will allow you to save heat indoors and protect it from the penetration of wind and frost. For the facade in most cases, material with insulation is used.

- After arranging the insulation layer, you need to take care of the spillways. They must be installed above the window and doorways, over the canopies and ledges of the building, above the base and above the joints of the panels.

- Further, the installation of metal siding continues with the installation of the siding panels themselves. Before installation, you need to install the internal and external corners, install the platband and cornices. After preparatory work, the building begins to be faced. Metal siding under a tree or stone is cut to the desired size and fixed using equipment.

- The final stage is the painting of metal surfaces (if necessary). The colors of metal siding are best chosen based on the overall exterior or design that was conceived.

Recommendations for installing siding

During installation, it is necessary to remember some rules on which the final result depends:

- The direction of the elements during installation is determined by the size of the plates and the height of the building.

- Excess lengths and widths are removed with a hacksaw.

- At installation it is necessary to remember about expansion gaps.

Due to its unique features, metal siding in stone, wood or brick is in great demand among builders and owners of private houses who decide to clad their homes.