Composite tile in the design of a country house: interesting options (22 photos)

Content

The market of roofing materials is diverse, potential buyers can choose an inexpensive "euro-slate", metal tiles, bitumen or ceramic tiles, seam roofs made of copper and titanium, natural slate. The cost of these materials ranges from 2-3 cu for "euro slate" up to 200-250 euros for exclusive varieties of natural slate. Each proposal has its own advantages, but the composite tile has incorporated all the best sides of all roofing materials. They developed and launched production of these products in the middle of the 20th century in New Zealand, they appeared on the domestic market 10-15 years ago and caused controversy among professionals. Today, composite tiles occupy a worthy place in the assortment of leading companies, successfully competing with metal and soft tiles.

What is composite tile?

Roofs of houses should be beautiful, reliable, durable and affordable. This is what most property owners around the world think. The most popular roofing materials are metal and bituminous tiles. The first one is appreciated for its affordable cost, easy installation, durability, but at the same time it is criticized for color monochrome and poor snow retention, increased noise level during rain. Flexible tiles are devoid of all these shortcomings, but have a higher cost and are characterized by increased demands on the base. As a result, roofers lay expensive waterproof plywood under it and use a lining carpet, the cost of which is close to the price of tiles. As a result, the cost of the roof increases by 2.5-3 times, compared with the roof of metal.

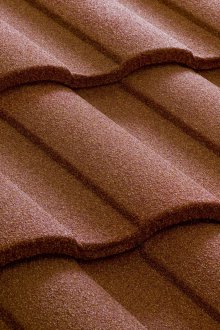

Composite tiles, which has the following original structure, were able to combine all the advantages in one material:

- steel sheet 0.4-0.5 mm;

- anti-corrosion layer from aluzinc;

- acrylic primer;

- decorative layer based on acrylic resin;

- basalt granulate to protect against mechanical damage and reduce noise;

- a layer of acrylic glaze.

The bottom sheet is protected by a primer and an aluminum-zinc anti-corrosion layer. Such a device of composite tiles guarantees a long service life and excellent technical characteristics.

An important feature of the material is its modular design. Unlike metal tiles, which are produced in sheets of various lengths up to 8 m, composite tiles are produced in short sheets of 40-45 cm in length. This gives it a number of technical advantages over cheaper metal tiles.

Advantages and disadvantages of composite tiles

Like any material, composite tiles have their pros and cons, but manufacturers do not hide disadvantages from buyers. In fact, it is one - a rather high cost, but it must be borne in mind that the installation of roofing material does not require such costs as in the case of flexible tiles. Another disadvantage for a long time was a strong surface roughness, for this reason dust accumulated on it, and there was practically no chance to get rid of dry leaves and needles on the roof. Manufacturers not so long ago found a way out - they began to pour basalt granulate with a layer of transparent acrylic resin.Due to this, the roughness became more streamlined and the dust became easily washed off by rain water.

All the disadvantages of composite tiles can not compete with the advantages of this material. Among its main advantages:

- high installation speed;

- flawless appearance;

- good snow retention ability;

- noiselessness;

- wide range of operating temperatures;

- a wide selection of shades and shapes;

- long service life;

- minimum amount of waste;

- ease of installation;

- light weight.

Composite tile houses look no less expressive than mansions covered with ceramic tiles.

An important advantage of the material is its compact sheet size, which greatly simplifies transportation. Where a truck with a body length of at least 4 m is needed for a metal tile, a pickup truck is enough to transport composite tiles. Compact pallets with roofing material are easier to store, and to supply sheets to the roof there is no need to attract special equipment.

Calculation and laying of composite tiles

To make an accurate calculation of composite tiles allow special programs that take into account the specifics of the profile, overlap, shape of individual roof slopes. It is always better to use this opportunity when making estimates. However, the need to pre-calculate the cost of roofing materials on their own at the planning stage of a house arises for all customers. To do this, it is necessary to calculate the area of all the roof slopes, after which it is necessary to determine the useful area of the composite sheet. It will be 10-20% less than the total area of the tile sheet. After this, it is necessary to divide the roof area into the useful area of the composite and add 5-10% to the resulting number. The result is the number of sheets that will be required for roofing.

The installation of composite tiles on the crate, similar to that used for metal tiles, is being carried out.

The only difference in its formation is the step, which should be equal to the wavelength. So, for metal tiles, the most popular step is 350 and 400 mm, and the laying of composite tiles is done in increments of 370 mm. The top row of tiles has no fixed size; the crate is laid with a step of the wave from the bottom up. To determine the length of the top sheet, measure the distance from the crate to the ridge and cut the sheets to the desired size.

Installation from top to bottom and against the prevailing wind direction. First, the upper row is formed, then the second row is mounted under it. The composite tile is fastened with nails to the wave end at an angle of 45 degrees to the crate. At the same time, two sheets are punched at once - the top and the bottom, so they are securely fixed to each other. It is recommended to use special fasteners with hat-colored tiles and with a protective acrylic coating. In this case, nails will not stand out on the roof slope.

The installation of composite tiles on the pediment has certain specificity. Manufacturers of roofing material recommend bending the edge of the sheet at an angle of 90 degrees upwards at a distance of 40 mm from the edge. A seal is glued to the bend, to which the wind board is pressed. After that, the end plate is superimposed on the formed structure and nailed by roofing nails.

The main manufacturers of composite tiles

This roofing material is not produced in every city as a metal tile. Production technology has its difficulties, requires the use of specialized equipment. Among the most popular brands:

- Metrotile is a Belgian company offering 10 collections of tiles with different waveforms;

- Gerard - a New Zealand company that produces 6 different types of profiles;

- Tilcor is a New Zealand brand under which roofing material of 7 different types of profiles and 40 colors is produced;

- Decra - the Belgian company Icopal, under this brand, produces composite tiles in the Mediterranean and classic style;

- Luxard is a brand of the Russian company Technonikol, whose products are of high quality and affordable price.

The roof of the composite tile has a magnificent appearance and excellent technical characteristics. A wide selection of profiles of various shapes allows you to choose the material for buildings in a classic, modern, Mediterranean or American style. The assortment includes products that can be combined with log walls and exquisite decorative plaster. All this allows composite tiles to gain growing popularity around the world.