Fireplace tile: rules for choosing the right material (33 photos)

Content

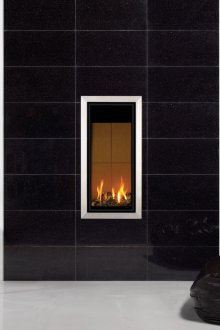

Fireplaces and stoves are an indispensable and traditional attribute of country cottages and village houses. They are an important part of the heating system and are installed in order to ensure optimal temperature conditions. However, they have one more important function - often they become the highlight of the interior composition and its main decorative element, therefore, when choosing a finishing material, an aesthetic component plays an important role.

What tasks does a facing tile for a fireplace solve?

- Improving heat transfer performance;

- Reducing the time required to heat the room;

- Decorative design;

- Simplification of maintenance of cleanliness;

For most modern people, building a fireplace or stove in a house causes positive emotions and relieves stress.

What should be a tile for facing a fireplace?

Since during the operation of the heating system there is a sharp temperature jump, most materials are simply not able to withstand thermal influences, therefore, to finish the furnaces, they choose a special tile, which should be:

- Heat resistant. The evidence that the tile has such properties is the capital letter "T", which is applied to the packaging of the material. High-quality heat-resistant tiles for stoves and fireplaces can withstand heating up to 1000 degrees. If the letter 1 is included in the set, this means that the ceramics were single-fired, the number 2 indicates that the tile was hardened twice in a special furnace.

- Strong. Facing tiles for stoves and fireplaces should have a thickness of at least 8 mm. Otherwise, it simply cracks after the first heating.

- Heat conducting. The more heat the fireplace tiles transmit, the faster the room warms up.

- Tight. A proper fireproof tile for a fireplace consists of microscopically small pores.

- Wear resistant. This indicator is determined by the established PEI standard. For decoration of fireplaces, material marked IV and V. is used.

- Moisture resistant. The optimal coefficient of water absorption is not more than 3 percent.

- Eco-friendly. The fact is that during the heating of the product some substances may be released, therefore it is extremely important that the heat-resistant tile made of tiles or terracotta does not contain harmful compounds that, when they enter the human body, accumulate and cause serious diseases.

- Not prone to expansion under thermal stress. The critical threshold for this indicator is 7-8 percent.

- Beautiful. Of course, a tile for facing a fireplace should carry an aesthetic load, otherwise the design of the room will look dull and boring.

Heat resisting tile: types and varieties

Today, the building materials market provides a fairly extensive range of products for facing heating structures. Ceramic tiles for stoves and fireplaces are varieties.

Tile

This option is considered the most popular and in demand, but experts say that this type does not have the highest rates of heat resistance or density. Even the most heat-resistant tiles look very dependent on temperature changes. Some homeowners inadvertently choose a glazed tile. During use, the surface may crack and completely lose its sophisticated appearance. Also, do not buy products whose dimensions exceed 20 * 20 cm.

These models are not at all adapted for adaptation in cold rooms, therefore decorating the fireplace with tiled tiles, for example, in guest houses or summer kitchens is unacceptable.

Brick tile for a fireplace

Experts believe that the decision to wall the surface of an electric fireplace or stove with clinker is the most successful and profitable. This material is highly dense because it is made from high-grade refractory clays exposed to high temperatures. In addition to the important functional advantages, an incredibly beautiful design can be surely included in the list of advantages. A large number of color solutions are presented to the attention of buyers. A uniform tonal coating gives the tile increased wear resistance, since small defects in the form of cracks in clay are invisible under the decorative surface. The only drawback of this material is its inability to adjoin a brick. They have different indicators of thermal expansion, as a result of which the tile often deforms and quickly collapses.

Majolica

Unlike clinker tiles, the manufacture of which also uses high-firing clay, it has an effective layer of painted glaze. Such products win against the background of the others, rather, in a decorative plan, but because of their density and porosity, majolica should not be used for facing furnaces that are rarely heated.

Metlakh tile

Here we are talking, rather, not about the name of the material, but about the properties of the products. Ceramic tiles for fireplaces of this type should have a matte surface, a uniform color and a zero coefficient of water absorption. It also has an incredibly beautiful design; intricate textures and ornaments are applied to the surface of the “models”.

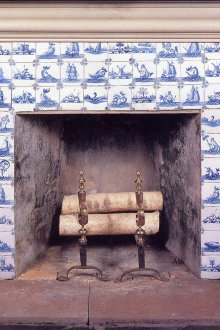

Tile

The main advantages of this cladding are environmental friendliness and impeccable design. It is because of these indicators that it is worth paying attention to the tiles. In modern stores you can buy exquisite handmade materials. With the help of them you can create truly unique pieces of art.

Terracotta tile

It is made manually or mechanically from red clay. Glaze is not applied to the surface of the products, so the color palette is not so diverse: terracotta tiles have only a few varieties and are available in yellow, pink and red-brown colors. That is why there are often options that mimic stones or bricks.

With regard to functional features, terracotta models withstand temperatures up to 1100 degrees, have high rates of heat resistance, impact resistance, heat transfer and resistance to temperature extremes. Given the thermal expansion capabilities, experts recommend finishing it with natural brick stoves.

Porcelain Tiles

One of the most durable and durable materials. To become so strong, it is burned in a special furnace at a temperature of 1200-1300 degrees. In the manufacturing process, components such as stone chips, various types of clay and other “useful” additives are involved. This heat-resistant tile has the highest hardness coefficients in its class (on a ten-point Mohs scale it is marked at 8), the calcined mass practically does not absorb water (0.5%), it is extremely resistant to temperature extremes and, unlike terracotta tiles, is resistant to chemical cleaning means.

Fireclay tiles

Tiles of this type have a striking property of acid resistance, which is why it is used in most cases in appropriate rooms.Among the huge number of advantages, one can single out the ability to exist quietly in rooms that are rarely heated and where the freezing temperature is kept almost all the time. It should also be noted the resistance to deformation, the thickness of the products and the surface roughness.

Some styling information

When choosing a tile for a stove or fireplace, pay attention not only to the quality of the materials (for example, facing a fireplace with gypsum tiles is impossible in principle), but also to the wrong side. Special notches must be applied on it to improve adhesion to the surface of the structure.

Strengthen the design using aluminum corners. Also, a metal network with cells no larger than 150 * 150 mm is great. It is laid between the tile and the concrete or brick surface of the furnace and is mounted on self-tapping screws or nails.

Before you begin laying the cladding, it is necessary to cover the network with a mixture of cement, clay and sand. Only glue based on aluminate cement can be used as glue, to which various chemical and polymer additives are added.

To hide the seams, grout is used, and so that the distance between the trim elements is the same, special crosses are used.

As for the cost of materials, chamotte, terracotta and clinker are considered the most popular in the budget segment. The luxury class includes a tile and natural marble. Porcelain stoneware and tiles are most rarely bought.