Laminated flooring

Since the beginning of the 90s, laminated parquet, as an alternative to other floor coverings, was introduced by a Swedish company. Prior to this, starting in 1923, this type of material was used for the production of decorative countertops, tables and other household items. For many years, the technology improved and in 1977 the idea came to manufacturers to start the production of laminated flooring. The basis of the product was paper, pressed under high pressure using special resins. With the development of production and the introduction of new developments, laminated flooring, created as an alternative to natural coating, is started to be produced not only from paper, but also from waste from the woodworking industry. After the introduction of laminate flooring in 850 stores in the United States of America in 1994 as a new, practical, easy-to-install, and inexpensive coating, a new era of this material began. Laminate flooring has significantly suppressed the construction market, such materials as carpets, natural wood flooring, ceramic tiles, vinyl coatings and in a relatively short time become a popular and sought-after product.

What is modern laminate flooring

Laminated parquet is not a type of natural parquet - it is a multilayer synthetic material, which is a combination of wood fibers, melamine and phenolic resins. High-quality paper is used as a protective decorative layer. The technological process consists in the gradual saturation of wood particles with resins. The next stage of production is the formation of a sheet that passes under high pressure and at high temperature. The main ingredients of the coating are wood particles, which make up about 82% and only 18% have a special composition of plastic resins. The quality and composition of the special glue used to connect the finished sheet with the top and decorative layers to a large extent depends on the strength and wear resistance of the final product.

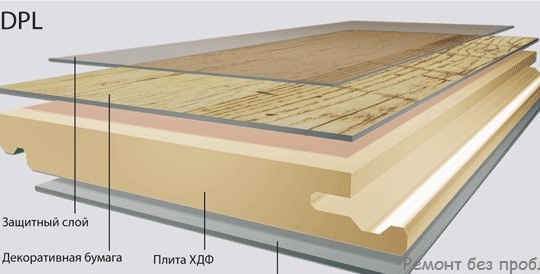

As a rule, high-quality laminated flooring by well-known manufacturers consists of 4 layers, each of which has its own functional purpose:

- The upper, stable melamine layer, in the form of a thin and strong film, is protective and contains paraffin, rosin and antiseptics. The basis of this layer are synthetic resins and various additives. As ingredient additives, crystalline particles of aluminum or corundum can act, which takes the second place after diamond in hardness. Products with the addition of these particles belong to a higher cost category, but the excellent quality of the protective surface allows them to be classified as coatings with a high degree of wear resistance. Additional processing of a stable surface with special compounds allows you to achieve high strength, protecting from stains, scratches, dents, as well as from fading when exposed to ultraviolet rays or chemical compounds.

- The decorative layer consists of a sheet of paper on which a high-resolution photograph is reproduced. This layer makes laminate flooring beautiful, aesthetic and gives a special elegance. The photograph can be reproduced drawing, patterns, various types of wood, natural or artificial stone. The design and structure of the surface can be limited only by imagination. Trends in modern architectural fashion are aimed at imitating natural materials. Many laminated coatings are difficult to distinguish in appearance from a particular type of wood, brick or stone.High-quality products of well-known manufacturers have good resistance to fading, which allows you to persist for a long time without changing the decorative pattern of this layer.

- The base (core) is the main layer, which is a plate obtained by compression under high pressure. Consists of 80% high density wood fibers. The strong structure of the plate allows you to withstand local impacts and it does not form dents from the pressure of high-heeled shoes. Product specifications and the quality of the final product largely depend on the strength and stability of the plate. When choosing a laminated coating for rooms with high traffic, it is especially necessary to focus on the mechanical stability and increased moisture resistance of the main layer.

- The lower balancing (stabilizing) layer is a moisture resistant substrate that is able to compensate for surface pressure, provides structural stability and increases the rigidity of the panels. In addition, this layer has soundproofing properties and performs noise insulating functions.

In products of some manufacturers, which are three-layer, a stabilizing layer is not provided, but for a quality installation it will be better to buy this material additionally.

Laminate flooring has a wide color spectrum, and is characterized by a variety of textures. Collectible products offer drawings, patterns and imitations of natural materials developed by professional designers. Some manufacturers practice the production of individual orders based on original photographs of customers.

It looks beautiful and laminate flooring with a glossy or embossed structure allows creating more interesting interiors. But it is worth remembering that gloss is more prone to scratches, and it is difficult to remove dirt or grease from a textured surface if it gets into it. In rooms with a large number of people it is worthwhile to install more durable and wear-resistant products with a matte finish.

Laminate flooring is a very strong and durable coating and, with proper maintenance and operation, you can count on long service life without any problems.