Wall panels - the best solution in cases where the main task is a minimum of cost and effort. They are simply mounted, and the choice of colors and textures is unusually huge, both from natural and from artificial raw materials. Today, wall panels have gained considerable popularity and success among consumers, despite the fact that they appeared on our market relatively recently.

What types of wall panels exist

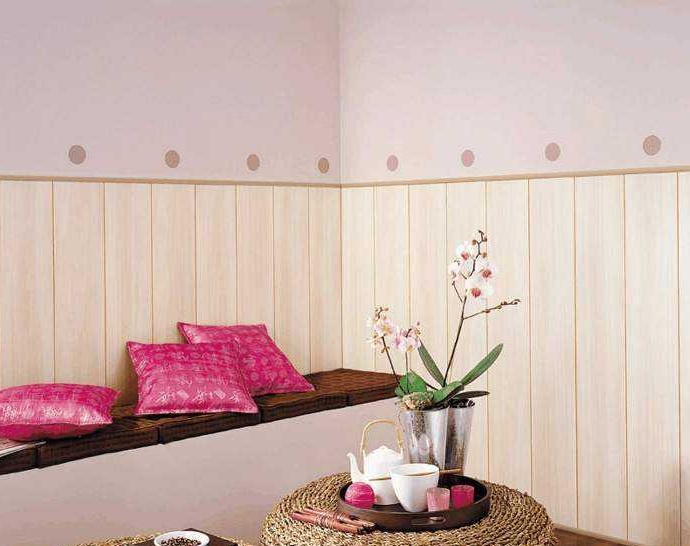

Rack Mounted Panels

These are planks with a length of 2400 - 3700 and a width of 125 - 300 mm, the thickness of which is from 8 to 12 mm. Most in demand in cases of cladding rooms with a small area. For their installation, a lath made of wood or metal will be required. The panels are connected due to the presence of a groove and a spike (or there are only grooves and tabs that connect the two panels, in this case a gap is formed). The panel to the crate is fixed using brackets or a self-tapping screw (in the groove). For the manufacture of rack type-setting panels, chipboard, fiberboard, PVC and MDF are used.

Tiled stacked panels

square in shape, the size of which is usually from 30 x 30 to 98 x 98 cm, by the way, very convenient for laying out various patterns, combining all kinds of shades, as well as texture. Fastening panels to the wall is usually done with glue or clamps, and they are interconnected only using grooves and inserts in them. Chipboard, fiberboard, PVC and MDF also serve as material for the manufacture of tiled typesetting panels.

Sheet wall panels

significantly facilitate the work of wall decoration due to the large size - from 1, 22 to 2.44 m, having a thickness of 3 to 6 mm. The surface of such panels is a multilayer structure with imitation of stone, wood or tile. Installation is done with glue, and the seams are hidden using moldings. For the manufacture of sheet wall panels, fiberboard impregnated with resins is used.

In addition to the existing three main decorative types of wall panels, there are also structural ones for the construction of internal walls and various partitions. These include both concrete panels and sandwich panels for modular homes, which are finished walls with insulation, as well as moisture and vapor insulation inside. Sandwich panels are used mainly for summer houses and country houses.

The material of which the wall panels are made

Natural wood panels

Most often made of oak, cedar, maple or alder. Ideal for residential premises, primarily because of its environmental friendliness. If you install them in rooms with high humidity (bathroom or kitchen), in this case, you should choose panels with a wax coating that repels water, as well as dirt.

Particleboard panels (chipboard)

The manufacturing process is based on the method of hot pressing of shavings and sawdust, similar to wood, but less durable, because subject to temperature changes and humidity levels, and therefore are only suitable for decoration of dry rooms.

Fiberboard (wood-fiber boards)

Also made by hot pressing, but with the use of wood and other plant fibers, they are less susceptible to moisture, environmentally friendly, however, are not recommended for rooms in which there is direct water.

MDF panels

This is a new material based on MDF boards created by dry pressing (fine wood chips are pressed) at high temperature and pressure. During heating, lignin is released from the wood, which serves as a connecting element. The material withstands sufficient loads (suspended cabinets and shelves), and is also resistant to high humidity, has heat and sound insulation, is hygienic, durable, in other words, it is quite high quality. Moreover, there are even refractory MDFs.

Glass panels

Designed to create photographic drawings that require a durable base, in this regard, they have a number of disadvantages.But with careful use they can last quite a long time, especially since manufacturers are interested in using modern technologies, which positively affects the strength and protection of the glass surface.

Gypsum vinyl panels

The material into which the well-known drywall has outgrown today is used to create walls, partitions and even ceilings. The new material is the same drywall with the only difference being that it is covered with vinyl instead of cardboard, which compares favorably with its predecessor. The panels are endowed with a finished work surface with a specific pattern, and they are also quite durable and reliable.

3D panels

The new design solution, contributing to the creation of their individual style, is made of fashion panels and bamboo - a material representing a new decorative range of sculptured textured panels painted in different colors using acrylic paints (glossy or matte finish). The panels can create a stunning effect and turn the interior of the room into a spectacular space.

PVC panels

Plastic wall panels also represent recent material made from solid polyvinyl chloride with a minimal amount of softener. Panels can be safely used for almost any room, even in showers, because They have a number of significant advantages: waterproof, fireproof, hygienic, with a long service life. Plastic panels are the most popular variety among their “classmates”. This has several advantages. Let's take a closer look.

Plastic Panel Properties

- Environmental friendliness. It is worth noting that polyvinyl chloride is used for the production of food packaging, pipes, medical equipment. According to the rules of SES, finishing PVC panels are recommended for schools, sports and medical institutions.

- Fire resistance. It turns out that the ignition temperature of the panels is +370 degrees, while the panels from fiberboard and particleboard light up at +250 degrees. But this is not all: as experiments show, PVC panels emit 2 times less smoke when burning than panels made of particleboard and fiberboard. And when tested for toxicity, it turned out that the combustion products of particleboard and fiberboard are one and a half times more toxic than their "classmate". Also, do not forget that the finishing panels are classified as self-extinguishing materials.

- Moisture resistance. Wall panels, due to their flat surface, absolutely do not retain moisture, and the absence of pores helps microbes and molds to not get along on the wall surface. That is why the material is often used in the bathroom and in the kitchen.

- Easy installation. It’s not a secret for anyone that installing panels is not difficult, even a not very experienced master can handle this. The material does not require any preparatory work and surface leveling. Moreover, the damaged part of the structure is easily replaced.

- Decorative abilities. Plastic panels have a wide selection of colors and shapes. There are options with a printed pattern on the surface using thermal film. The material is able to decorate any surface, which is why it is considered the most popular finishing option.

Plastic Panel Size

The thickness of the panel can be divided into two subtypes - these are 5 mm and 8.9.10 mm. On the second subtype (size 8-10 mm) are moldings of the same size.

- Lining. The panel is 3 m long, 10 cm wide and more rare 12.5 cm (has a double profile). The most popular are the “European” with a wide lock and the other less popular option with a narrow lock is “polka”. It is produced mainly in white, less commonly found in color.

- Panel. The most popular lengths of plastic panels are 260, 270 and 300 cm; the width can be 15 - 50 cm, but the most common size is 25 cm. The panel can be painted, varnished or coated with thermal film.An almost invisible seam when assembled is the main difference between the panel and the lining.

- Sheet. PVC sheets can also be called PVC plates. The width of the sheet can be 80-203 cm, the length is from 150 to 405 cm. The most popular foamed PVC sheets, while the top layer of the panel can be impact resistant and smooth.

The advantages of using wall panels

Using wall panels as a finishing material, you can avoid such preparatory moments as aligning the walls, as well as removing old plaster, wallpaper and paint, i.e. pre-wall decoration. In addition, for the installation of wall panels do not need special tools or equipment, as well as the special qualifications of the master. All that is needed is a stapler, nails, wooden bars and the panels themselves. Among other things, wall panels will provide excellent sound and heat insulation and masking of computer, telephone and other electric cables in the room. They don’t need special care either; all that is needed is to wipe them once a month with any detergent or just a damp cloth. And if necessary, damaged elements are easily replaced. But usually wall panels have a long service life, they are durable, hygienic and resistant to mechanical stress - all this will eliminate the need for annual cosmetic repairs.

Wall decoration in the bathroom: beautiful design options in the photo

Walls in the bathroom: a variety of finishing materials in a trendy design

The use of artificial wood in modern design projects.

Stencils for walls: painting options

Wall decoration with cork wallpaper: the nuances of using natural material

Wall painting in the apartment: finishes and creative design techniques

Wall painting in the interior - your unique home design

Textured Venetian plaster

Moldings: 100 ideas for interior use

Wall panels for modern interior decoration

Choosing the perfect wall color for your bedroom

How to decorate the walls in the corridor practical and beautiful?