Types of Polycarbonate

The building materials industry constantly pleases its customers with new products. Today, various types of polycarbonate are produced. This most modern polymer building material has completely unique properties: relatively light weight, excellent thermal insulation, high transparency, excellent flexibility and excellent strength, withstands a wide temperature range, fire retardant and durable. Thanks to the combination of all these properties, polycarbonate has no analogues. Each type of this material has a certain set of different parameters, which helps to decide which polycarbonate to choose for a particular case.

The main types of polycarbonate

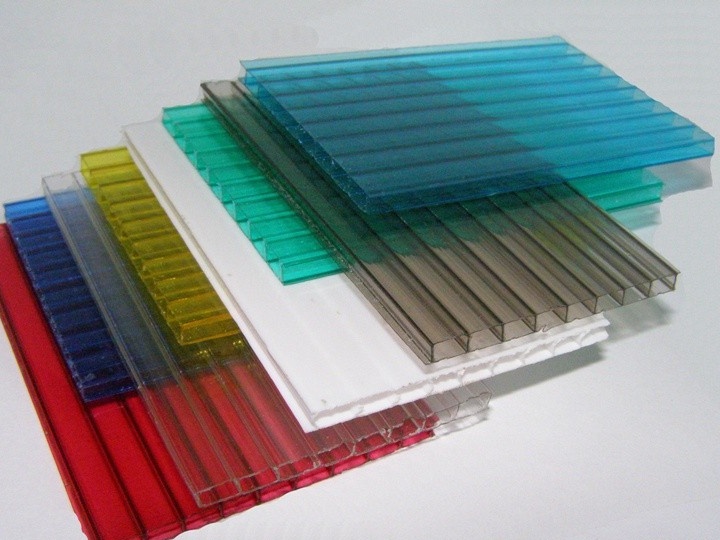

These types of polycarbonate differ in production technology and some properties. And for casting various products of complex configuration, polycarbonate granules are used.

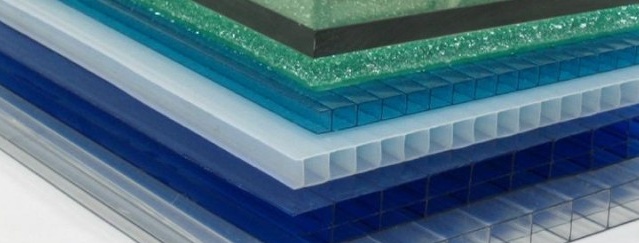

- Extrusion method also produces cellular polycarbonate from such granules. Molten granules are pressed through a die (special form). The profile and design of the finished sheet is determined by the design of this form. Extrusion allows you to get a hollow sheet of several layers, which connect the ribs. These ribs are parallel to the long side of the sheet, which makes it very flexible and durable even with minimal sheet wall thickness. Air gaps provide excellent sound and heat insulation for cellular polycarbonate products. This polymer also has high heat resistance and fire resistance, high impact resistance, resistance to atmospheric precipitation (hail) and aggressive environments, low specific gravity (glass is 16 times heavier), excellent transparency (about 85%). This material is safe to use (in case of damage, sharp fragments and cracks do not form). Cellular types of polycarbonate are widely used for the "glazing" of loggias, winter gardens, greenhouses, telephone booths, stops. This material is perfect for covering roofs, arches, roofs, creating false ceilings and partitions. It is also used in the advertising field (volume letters, scoreboards, light boxes).

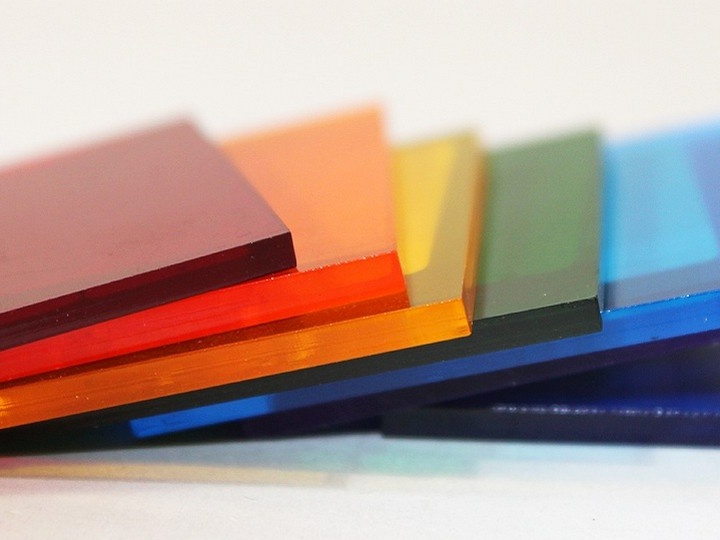

- A transparent solid plate with a thickness of 2-12 mm is a monolithic polycarbonate. This material is identical in useful properties to cellular polycarbonate, but it is more transparent (90%), several times stronger, much heavier and more expensive. Often, protective helmets and shields for law enforcement agencies, glazing of armored vehicles and aircraft, premises of financial institutions, gyms and stadiums are made from this polymer. It is also used for the construction of fences and industrial greenhouses. And outdoor advertising does not ignore this material (signs, pillars). Therefore, which polycarbonate to choose for your purposes is up to you.

Required Polycarbonate Protection

This unique material, however, collapses quite quickly under the influence of solar ultraviolet rays. Therefore, the necessary protection of polycarbonate (a special stabilizing ultraviolet layer) is applied directly in the manufacture of the product on one or both sides of the sheet.

Polycarbonate may need to be protected from scratches. Then, in the manufacturing process, the sheet is coated with a special hard layer, which gives it high abrasion resistance. There are also products coated with special layers that reflect infrared radiation or prevent fogging.