Wall panels to decorate your home

If you are planning to repair a room in a country house or city apartment and are now at the stage of choosing finishing materials for the walls, then this publication can be very useful for you. About a couple of decades ago, our compatriots did not have so many options for decorating the surfaces of residential or utilitarian premises of a dwelling. Nowadays, the range of stores offering finishing materials is so great that deciding on the choice of one of the types of materials becomes a difficult dilemma. In this publication, we would like to touch on the topic of choosing wall panels for decoration of premises for various purposes.

Currently, this decoration material has become quite popular not only for office owners who want to make cosmetic or full-scale renovations of premises, but also for homeowners who need to decorate rooms with a variety of purposes. Wall panels are available in a wide range of colors and textures, they are easy to install, affordable, made from both natural and artificial raw materials, and most importantly, they can be mounted on any surface and hide their imperfections.

Classification of panels for wall cladding

Wall panels differ in size, shape, method of manufacture and installation. Depending on what type of panels you prefer to decorate your room, the final appearance of the interior will develop.

In shape, all wall panels can be divided into three groups:

- rack and pinion;

- tiled;

- leafy.

Rack Mounted Panels

As the name implies, this type of panel is a long strip (usually the length ranges from 2.4 m to 3.7 m) with a width of not more than 30 cm and a thickness of 9-12 mm. Because of these sizes, slatted panels are most often used for wall cladding in small rooms or rooms with complex geometry (a large number of angles).

For the installation of rack type-setting panels, it is necessary to create a crate of metal or wood. The panels with the crate are connected using brackets (a special construction stapler will help you) or using self-tapping screws. Such installation is easy to do on your own. Rack panels are made of MDF, chipboard, fiberboard and PVC. Usually, special fittings are attached to the panels, which will help complete the image of the room cladding.

Light-colored slatted panels help visually expand small spaces such as a bathroom, corridor or kitchen. The vertical arrangement of rack wall panels will help to visually increase the height of the rooms.

Tiled panels for walls

This type of panel is made in the form of a square, the sides of which can be from 30 cm to 100 cm long. Such wall tiles are usually fastened with glue or with clamps. One of the distinguishing features of tile panels is that the connection of parts between themselves is carried out only with the help of grooves and inserts in them. By combining the different arrangement of panels on the plane, it is possible to achieve interesting finishes not only with color schemes.

Using tile panels with different wood patterns, placing them at different angles and at two or three levels, it is possible to create an original and unique design of accent walls. If you add a built-in backlight to this option, you can enhance the effect.

Sheet panels for vertical planes

Obviously, among the three options for panel shapes, this one is the largest in size. Most often, sheet panels are made of fiberboard or PVC.The working surface of the panel sheet is a multilayer structure with a printed pattern or texture that imitates wood, stone or other options for facing material and their combinations. As a rule, sheet panels are mounted with glue, and the joints between the products are filled with moldings. The main feature of sheet panels is the ability to cover large surfaces.

Choosing material for wall panels

In the manufacture of panels that serve for surface lining, a wide variety of raw materials are used, from natural wood to plastic. Most often, several types of materials are combined. But on sale you can find options made only of wood, for example, or only of glass. Obviously, the cost of such products will be higher than usual.

Not only the general atmosphere in your home will depend on what materials were used to make the decoration materials, but also the well-being of the household and even their health.

Panels made of wood - natural insulation and beauty

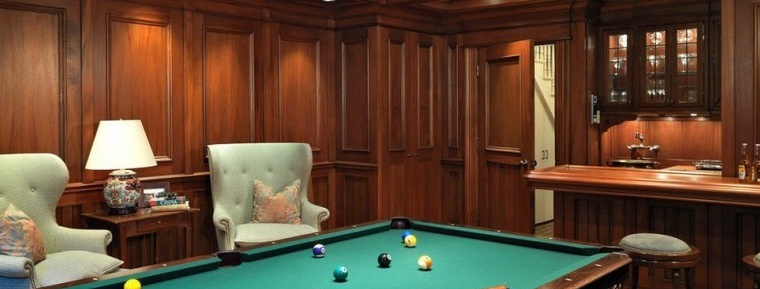

All homeowners who want to create a healthy and warm atmosphere in their rooms should consider purchasing natural wood panels. Most often, such panels are made of oak, linden, maple, cedar and bamboo. The room, in which wood paneling was applied, looks not only attractive and respectable, it is full of natural warmth and cordiality.

As a rule, wooden panels are slatted or tiled. The exception is the mosaic panel, the basis of which consists of fiberboard, covered with pieces of natural wood of various species.

Wooden products, as you know, have limitations in their scope - rooms with high humidity for them can be fatal. The tree absorbs moisture very well, and when it begins to dry, it begins to crack, takes on a more porous form and can ultimately dry out completely. This problem is easily solved with the help of special coatings, varnishes. But in this case, the environmental friendliness of the facing material will suffer. The disadvantages of natural material as a basis for wall panels can be called quite a high cost.

Particleboard wall panels

Of course, chipboard panels are significantly inferior to wooden products, but more than compensate for their own imperfection with an affordable price and ease of manufacture - woodworking waste was used in the manufacture of this type of finishing material.

Without coating, chipboard panels do not look very respectable. With the help of a plastic coating, it is possible to achieve many options for color and textured solutions.

From the point of view of environmental friendliness, particleboard panels are very harmful to humans and the environment. In the manufacturing process, harmful adhesive compositions are used.

Particleboard wall panels are available only in slabs, due to the large weight of the products, they have limitations in installation methods. This version of the material for wall panels does not tolerate high humidity, so they are most often used to decorate hallways, corridors and other utilitarian rooms without sudden changes in temperature and humidity.

Panels for walls made of fiberboard

As you know, fiberboard is a material that is obtained by pressing wood fibers at high temperature. We can safely say that fiberboard is a material that combines natural heat and dynamism of modern technologies. Due to the technological features of production, fiberboard panels can be presented in a wide range of color and texture solutions. In combination with low cost, this makes fiberboard wall panels the leaders of the domestic market of facing materials in their segment.

Panels made of fiberboard can be mounted both on the crate, and directly on the wall.But the surface will need to be prepared - it is better to get rid of large differences in the plane, to clean and dry the surface. The panels are interconnected either by a locking method or by means of grooves.

Board or tile panels made of fiberboard are easy to install and can be replaced if necessary. The disadvantages of this type of material for the manufacture of wall panels include low moisture resistance. It is better not to use such products for bathrooms.

The working surfaces of fiberboard panels, in addition to the usual lamination, can be sheathed with fabric, leather, veneer, wooden mosaic or painted. The choice of colors and textures is truly unlimited.

MDF panels for wall decoration

Compared to fiberboard, MDF panels have a lower density and much lower weight. MDF boasts very good sound and heat insulation properties. MDF material is quite versatile, in addition to insulating properties, in the manufacturing process it can be given other qualities - moisture resistance, fire resistance, resistance to biological effects.

Unfortunately, the versatility of the material and enhanced technological properties push the cost of MDF to a higher level than fiberboard, for example. But in the process of operation, the high cost pays off trouble-free "work" finish.

PVC for the production of wall panels

PVC material as the basis for the manufacture of panels has long won the market of building and decoration materials. The point is the obvious advantages - high technological qualities (moisture resistance, heat resistance, wear resistance and durability), ease of installation and a wide variety of color and texture solutions.

PVC panels are available in all three versions. Panels with a base of MDF or fiberboard, covered with PVC film can create a decent imitation of stone or wood, brickwork or ceramic cladding.

The only, but very serious drawback of PVC panels is their artificial origin and all the ensuing consequences for humans and the environment.

Gypsum vinyl wall panels for decoration

Absolutely everyone knows about such material as drywall, its popularity in the construction market can hardly be overestimated. It is used to create walls, partitions, ceilings and cladding. Modern technologies have brought to the market of building and finishing materials a new product - gypsum vinyl wall panels. At the heart of this material is the same drywall, but covered with a layer of vinyl. Having strengthened itself as the decoration of public buildings with high traffic, gypsum vinyl began its procession through residential premises. Unlike drywall, this material is stronger and more durable, has an already finished surface with a printed pattern or plain coloring.

By combining various shades and even materials of wall panels, you can achieve original and unique results. For example, combining gypsum vinyl panels with mirror surfaces, you can get a completely extraordinary interior of the living room or bedroom, in these rooms such combinations will be most appropriate.

With the help of moldings of various thicknesses and modifications, inserts into the space between the panels of textile elements made of leather or pasted over with embossed wallpaper, you can personalize any interior design. In living rooms, bedrooms and even children's rooms, such compositions will look luxurious.

Using silver-plated or gold-plated moldings to decorate the space between the panels, you can create a beautiful interior in the classical style or Baroque and Rococo styles.

An interesting and practical option for using wall panels is to design a certain apron around the entire perimeter of the room. Such techniques are relevant for children's rooms (where the lower part of the walls is most affected and will need more frequent cleaning), large kitchens combined with a dining room, hallways and corridors.The upper part of the walls can be painted or framed using wallpaper in a monophonic version, or using a print.

3D embossed wall panels

This type of panels appeared on the domestic markets not so long ago, but has already managed to earn the attention and love of many designers and homeowners. Wall panels have a three-layer structure, the base is usually made of MDF, fiberboard, drywall. The working relief surface, as a rule, is made of gypsum (sometimes wood or metal reinforcement is used, but the cost of such products will be significantly higher) and covered with a PVC film. On sale you can find relief panels covered with leather (artificial or natural), fabric, veneer, or simply plain enamel.

Modern technologies allow the range of embossed panels to constantly expand, increasing the scope of their application. 3D panels are used not only for decoration of personal and utility rooms, as a total wall decoration or partial integration, but also for highlighting individual segments of the room, cladding and highlighting decor items, furniture or structural features of buildings.

As a rule, embossed panels are produced in the form of sheet modifications. Tiled options are less common, but they are large (sometimes to create a bas-relief, but such models are not cheap, and it is often necessary to make a purchase on order, are rarely available).

Soft panels for a creative interior

Original design, excellent sound insulation, easy care and safety - weight is the advantage of using textiles or leather to create a panel design of walls (all or only accent).

Artificial leather is not as expensive as natural material, and the visual effect creates no less impressive. Caring for her is incredibly simple, just cleaning with a damp sponge and wiping the surfaces dry. Such planes are not afraid of moisture, direct sunlight and temperature extremes. Nevertheless, it is difficult to imagine the use of such panels in utility rooms. The most appropriate and harmonious they look in the living rooms, bedrooms, offices and children's rooms (where, among other things, they can also perform the function of safe cover)

Leather-covered panels, even in a non-soft version, look luxurious. For the design of the living room or study, as well as the wall at the head of the bed in the bedroom, this option will be a great opportunity to raise the status of the interior.

A few simple tips for choosing the right wall panels:

- when buying panels, pay attention to the marking, all labels indicate indicators of flammability, flammability, smoke formation and toxicity (if you purchase fully artificial products, pay special attention to these indicators, for all four levels, the higher the number on the marking, the worse);

- take into account the features of the room for which the panels will be purchased - temperature differences, humidity and fire hazard will be the main indicators;

- carefully examine each packaging with wall panels for defects, if you find them at home - it will be extremely difficult to prove the fault of the manufacturer or the shipping company;

- pay attention to the color of the selected product, panels from different parties may differ by one or two;

- check the integrity of the lock joints;

- long rack panels can visually expand the space, and for large rooms tiled or sheet products are suitable.