Facade siding - advantages and disadvantages

The appearance of siding in our country was preceded by a long history of the production of frame-panel materials for cladding buildings. The technology for cladding the building frame using cladding sheets of various materials came to us from America, which is why at first the siding was most often called the cladding board “American”. Initially, siding was made only of wood, it is easy to guess that the main disadvantage of such a finishing material was its high cost. With the advent of PVC and sheet steel sheathing material, the availability of siding has increased many times and the popularity of this type of decoration of building facades has spread among our compatriots.

Consider the options for materials for the manufacture of siding, as well as options for execution (design), colors and shapes of modern cladding sheets.

Types of siding for facing private houses

Wood siding

One of the first wood siding on the market of cladding materials. Most often, spruce and pine wood were used to make the cladding board. Initially, the siding was a board that was stuffed from the bottom to the top of the building frame with a slight entry of the product to the next one - this way of lining created a protective coating for the walls. The boards were painted or varnished to extend their life. Currently, siding can be mounted in two ways - butt and lap.

There are the following types of siding made of wood:

- false beam;

- block house;

- ship board.

Advantages of wood siding:

- environmental friendliness of the material;

- resistance to low temperatures (frost to minus 50 degrees);

- excellent heat retention properties;

- ease of installation.

Cons of siding made from wood:

- high fire hazard without additional treatment;

- inability to use in a humid environment without a special coating;

- requires additional protection against pests, moisture and the spread of fungus;

- relatively high cost.

Currently, most manufacturers use their sizes and shapes for production, this must be considered when planning a purchase. The profile is a wooden beam or board. From the point of view of care, natural material requires periodic staining or varnishing. If cracks in the material are formed due to drying of the wood, they must be putty.

Pulp and wood siding

Such a material is a panel made according to the MDF principle - based on raw materials is a mixture of wood fibers, which was pressed under high pressure and high temperature. Due to the addition of various resins to the composition of the mixture, it is possible to significantly increase the strength, wear and moisture resistance of the material.

Advantages of wood-cellulose panels:

- cost lower than wood siding;

- a wide range of textures and colors - the ability to choose almost any imitation of wood;

- the possibility of arranging the facade, which will "breathe";

- good heat conductivity;

- environmental friendliness of raw materials.

The disadvantages of the material:

- the deformed product cannot be restored; replacement is necessary;

- the cost is higher than that of plastic siding.

Plastic (vinyl or acrylic) siding

About half of all siding sales are in plastic products. The main advantage of this finish is the affordable cost of products. Among other things, PVC siding is durable, resistant to temperature extremes and the occurrence of burning, has a high resistance to corrosion and low weight, easy to install. It is very easy to look after vinyl and plastic siding - washing with a garden hose is usually enough.

Of course, such a material for facing has its drawbacks - with a strong impact, the integrity of the material can be violated, in this case it will be difficult to change one sheet, it will be necessary to remove almost the entire wall sheathing. In addition, BX siding does not hold heat well, therefore it is necessary to use a heat-insulating material complete with this facade cladding.

Metal siding

This type of facing material is the so-called “pie” - a multilayer structure of a metal core, soil and polymer coating. Let us dwell in more detail on the consideration of siding made using metal.

Aluminum siding in private construction and decoration it is used infrequently mainly due to the high cost. Most often, such a facing material is used in the decoration of facades of commercial buildings. But recently, private houses have also been faced with aluminum siding, to create an original and attractive image of the building's facade.

Pros of using aluminum siding:

- small all material;

- high strength;

- durability;

- material does not support combustion;

- it is possible to choose a smooth or embossed surface finish.

Cons of the material:

- low elasticity of raw materials - if a dent appears on the product, it will not bend back;

- there is a possibility of damage during transportation and installation - it may bend.

To share steel or galvanized siding the majority of sales of finishing materials account for, and it is precisely this that we most often call "metallic." It can be used for cladding facades of both public and private buildings. Galvanized steel is not used in its pure form - on top it is coated with polymer spraying (most often polyester or plastisol is used) or painted using the powder method.

Modern manufacturers offer both smooth siding panels and embossed (wood-like) products. Metal siding can be presented in the form of a herringbone (single or double), a shipboard, a vertical product (the so-called corrugated board), a block house.

The advantages of galvanized steel siding:

- the possibility of producing cladding all year round;

- strength;

- resistance to burning;

- long operation;

- resistance to weathering;

- corrosion resistance subject to product integrity.

Material disadvantages:

- poor soundproofing;

- low stability of the surface coating of products;

- low thermal insulation, the need for facade insulation;

- It is difficult to replace one sheet.

Facing the building frame with corrugated board allows you to visually increase the height of the structure - vertical stripes greatly contribute to this.

Zinc siding - This type of facing material is just beginning its march on the domestic market of building and finishing materials. The main obstacle to the distribution of material is the high cost. Even the high strength and durability of the material stop our compatriots from buying gray (“quartzite”) or black (“anthracite”) siding.

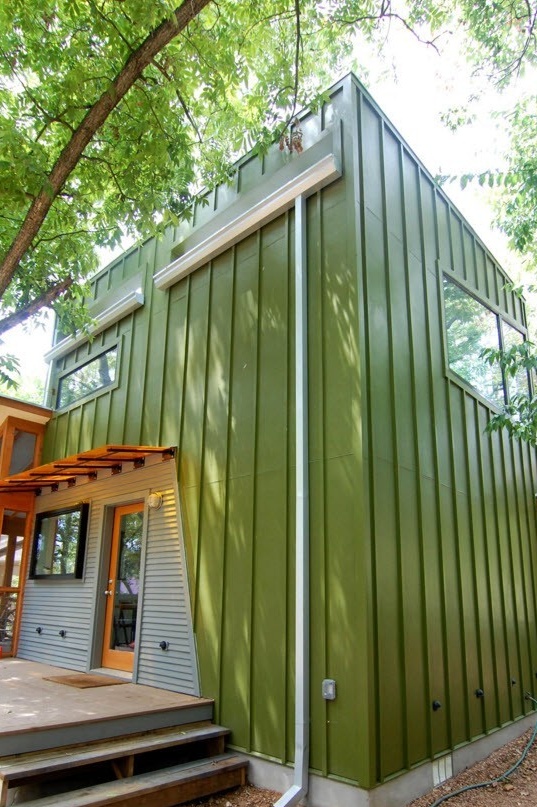

Original facade with metal siding

The most common way to create an unusual image of the facade of a private house building is to combine materials. The use of metal siding in combination with a wooden cladding board allows you to create original combinations. Smooth and textured surfaces, “warm and cool” color temperature - the cladding built on contrast is very attractive from the outside.

In addition to wooden surfaces, facade siding can also be combined with masonry. A harmonious combination can be achieved by effectively choosing a siding suitable for the shape and design of a house, part of the walls of which are made (or faced) with stone, there are wooden elements for fastenings or finishes.

Facing with metal panels semicircular surfaces, arches and other rounded shapes will create a difficult original, but completely unique image of the facade of the building.

Siding made of metal and plastic, brickwork, wooden surfaces, glass and concrete - surprisingly, all together can perfectly combine. The main thing in such combinations is to know the measure and adhere to the basic concept in the design of the facade.

Originality in the image of the facade, lined with siding, can be achieved through the use of material of unusual colors. No one can surprise anyone with all the shades of gray - choose colorful combinations so that your private house differs from the buildings on your street.

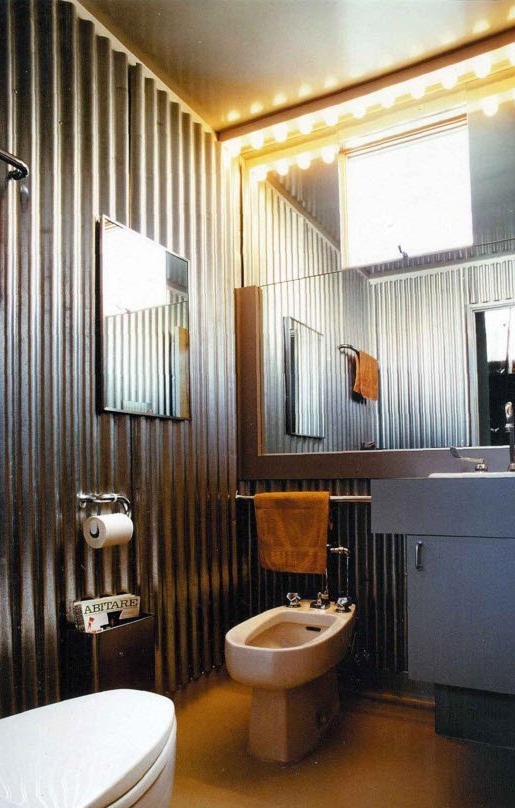

For siding, there may be applications for interior decoration. Of course, such a design is not suitable for every room and not every homeowner will decide on such an experiment. But one thing is clear - do not take up the originality of the interior with siding trim.