Sand concrete: description and preparation technology

Sand concrete appeared on the market not so long ago, about 15 years ago. But now it is difficult to imagine a modern building without it, because sand concrete is used in the construction of foundations, walls and partitions, for the installation of wear-resistant floors, the bonding of reinforced concrete structures, masonry work, and for interior decoration work.

The mixture consists of Portland cement, plasticizers and filler. All components are mixed in concrete mixing machines. Particular attention is paid to composition, since non-observance of proportions may result in poor quality. Sand concrete is produced in the form of a dry mixture or finished blocks.

The material has a lot of positive qualities: wear resistance, good strength, water resistance and frost resistance. These properties are achieved due to the content of Portland cement in its composition. The larger its volume, the higher the operational properties.

You can work with sand concrete at a temperature of more than 5 degrees. A work mix is prepared by mixing cold water and dry matter. The finished mixture forms a homogeneous dense mass of viscous consistency. Resistance to various mechanical factors depends on the ratio of dry mix to water. Therefore, maintaining proportions is very important. The mass is very plastic, so work must be done no later than three hours after the addition of water.

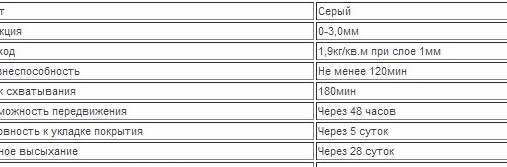

Working with the mixture is not particularly difficult. After pouring on the base, the solution is distributed evenly around the entire perimeter. At the time of hardening there should not be a quick drying of the surface. After two days, you can check the strength, and after a week to continue work. Final strength is achieved after approximately 4 weeks of pouring.

Preparation of mortar mixture:

- when mixing the solution, we strictly observe the proportions of water and the dry mixture, otherwise the mechanical strength of the material decreases;

- add a dry mixture to a container of water (temperature around +20 ˚С), the proportion for M-300 is 10 kg of the mixture per 1.8 liters of water, then mix the solution until the lumps disappear;

- wait 5 minutes, mix again without adding water;

- use the solution within 3 hours.

Technical characteristics of sand concrete M-300

The most popular brand of sand concrete is the M-300. Its application is very diverse. It is suitable for leveling and pouring floors, sand and cement substrates, eliminating flaws in pouring, building foundations. It is advisable to use this type of concrete when installing underfloor heating. M-300 is used as a coating and an intermediate layer in a heating device. The preparation of the mixture requires the correct proportions, since with excess water, delamination and cracking can subsequently be observed.

Sand concrete can be purchased ready-made, as well as made independently with the necessary components. The cost of industrial concrete is low, which makes it possible not to save on quality.