Metallic wallpapers: the unity of style and security

Metallic varieties of wallpaper arose as a response to the ever-increasing background of electromagnetic radiation from a variety of electrical appliances. It is known that the higher the frequency or radiation power of a radio signal, the higher the chances of a person constantly irradiated by him to get sick, for example, with cancer or leukemia. Today, with the abundance of cellular repeaters, power lines, radio and television broadcasting stations, the desire of the average person to somehow minimize their impact on his body is understandable.

Protective properties

The natural desire of a person to live in healthy and comfortable conditions resonated with companies that produce finishing materials. So, the efforts of development engineers created roll wallpaper products in which a thin layer of foil performs several useful purposes at once. Being glued to the walls and ceiling, this finish serves as a kind of protective screen that dampens well any background and directional electromagnetic effects from objects outside.

It should be especially noted that the natural background of the electromagnetic radiation of our planet by this kind of barrier does not overlap, since it has a very low initial frequency. But the signals of various man-made emitters (from mobile phones to high voltage power lines) are neutralized here very successfully. In addition to the protective properties, metal here bears a considerable aesthetic load. Its presence in the product also significantly increases the service life of the latter.

The subtleties of production

Metallic wallpapers consist of several layers. The basis of them is a canvas of porous paper. A layer of aluminum foil is tightly fastened with it, which is an order of magnitude thinner than human hair (about 17 microns). In turn, this metal coating is coated with a thin flexible film of paint that does not conduct electric current. Finally, embossing or drawing can be applied on the front side. The desired image is also carried out by dielectric varnishes and coloring compounds. Various chemicals and metal powders may be involved.

Advantages and disadvantages

At the time of gluing on the ceiling and walls, the peculiar finish receives natural grounding and therefore cannot accumulate an electrostatic charge. This kind of shielding from radiation can also serve as a noticeable obstacle to the normal functioning of various tracking and listening devices. The ability of aluminum to reflect thermal infrared radiation will be a good help in solving energy saving issues in the heating season. Such a metallic finish is water resistant and corrosion free. Therefore, even very humid rooms of the house without fear can be covered with such wallpaper.

True, there is one minus in all this positive: the metallized coating practically does not let air in and does not allow the walls to absorb excess moisture. To compensate for the deficiency, it will be necessary to ventilate the premises more often. And the most reasonable in this case (and not only) is to equip a high-quality air conditioning and ventilation system in a house or apartment.

In addition, the strength and durability of such a coating is in no way inferior to its protective properties. Walls so glued will not lose their original aesthetic and functional characteristics for many years. Extravagant wallpapers will not fade or fade. They can be washed regularly with modern cleaning products. In order not to damage the thinnest layer of metal, it is better to use a soft cloth or sponge.

Sticky notes

The glossy front layer shows well all the irregularities of the wall, so the metallized type of wallpaper is extremely demanding on the flatness and smoothness of the original bearing surface. In addition, the ability of walls or ceilings to absorb must be very good. Indeed, otherwise the glue simply will not be able to dry, since the metal screen will not allow moisture to escape into the atmosphere of the room.

Strips are glued strictly butt to each other. The glue needed is the same as for heavy vinyl wallpapers. When calculating the required number of rolls, it is necessary to remember the inevitable additional waste when fitting the picture (25-35%). During the gluing process, the electricity in the room must be turned off, since the combination of wet glue and conductive foil can easily provoke a short circuit and electrical injuries.

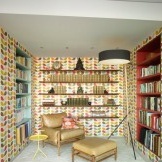

An even coating with a gold, bronze or silver tint will leave few indifferent. Through this design, every room acquires its share of sophistication and even luxury. A well-chosen pattern and texture combined with moire curtains can emphasize and enhance the overall impression of the situation.