We repair drawers with our own hands

In the modern market of furniture offers, you can find many types and designs of drawers. But now we are not interested in their appearance. Regardless of the quality of the guides and whatever the quality of the assembly, there are many cases where problems begin to arise over time. Most often this happens.

- when overloaded

- incorrect installation of guides

- exceeding effective life

- deformation of individual parts during operation

The above problems relate to the work of mechanics, which is used in modern furniture to extend drawers. With the box itself, the design - fewer problems. Let us dwell on them first.

Drawer Design Issues

The most common problem is the bottom of the drawer. There are two types of box bottom fastening. It can be safely said that 90 percent of manufacturers simplify production and make a laid bottom, which is attached from the bottom to the box. Attaches around the perimeter to the sidewalls. This greatly simplifies the technology, the bottom becomes another supporting part, which also takes on the role of the part that forms the geometry of the box box. What to do if there are problems with this type of bottom attachment.

Most often, the reason is insufficiently strong and thoughtful fasteners. The bottom is fastened with carnations to the front and rear, and guides are held from the sides. At first, such a scheme works quite tolerably, but over time, the nails become loose and the bottom leaves, even if the box is not overloaded. The way out is to replace.

Nails - forget it right away. Today, only the lazy and frankly mean ones use them. For repairs, it is most simple and effective to use furniture staples. A stapler for furniture is very inexpensive, staples are even cheaper. If your box is not loaded "I can’t do it myself," 8 mm brackets will suffice. They are easier to work without habit, they are less deformed and enter a sufficient depth. But if you are ready to pre-work out and fix the bottom more confidently, take 10 mm long staples. You can use red-hot nickel-plated - they are even stronger and do not rust. After - the procedure is simple. We remove the old fasteners and “shoot” with brackets the bottom around the perimeter. Under the guides too. It is not difficult to remove them - they are fastened with three screws on each side. In this case, you must not disturb the geometry of the box, so punch the sides in sequence.

You can use screws if you have difficulty getting a stapler and staples. You will need screws with a diameter of 3.5 mm. There are two generally accepted standards for the length of furniture screws of this diameter - 15 and 30 mm. In principle, 15 is enough. However, it may be that the box is made of a low-quality chipboard, which is porous inside, so it is better to use 30 mm screws.

Both of the above methods are also suitable for replacing the bottom of the box - you will need to cut out the material of the right size and fix it on the box of the box.

The second type of bottom attachment is the mortise bottom. Most often, this is thin plywood, which is glued to the slots on the walls of the box. Such a bottom very rarely causes problems, in most cases they are caused by its destruction. If a laminated fiberboard is used, one may encounter a situation where, due to plasticity, the glued zones simply break out of the grooves. This "disease" can be treated a couple of times by secondary smearing of the groove and gluing to the bottom, but still it is better to immediately change it. This is not an easy procedure, but with some skills it can be done.

- the box needs to be disassembled;

- to clean the grooves without violating their shape and thickness;

- order or cut a new bottom part of the desired size;

- reassemble the box by gluing a new bottom;

- give time to allow the glue to dry well. Do not load the box.

If the box is assembled using self-tapping screws or confirmations, this can be done easily. However, if studded joints were used, it is better to turn to specialists for disassembly if you are not strong in carpentry. The same actions are performed when you need to replace the plywood bottom. If it is cracked, damaged, deformed or lost its appearance.

Drawer hardware problems

In the mechanics of drawer extension, several types of guides are used today. Here we look at two. Transitional types also exist, but they are used by units. Or as an experiment, or to improve functionality without altering the main structure. We will not consider such types of fittings.

Roller guides and their "convenient" brothers - metaboxes

The advantage is simplicity, low cost, ease of installation, the design is such that the box closes under its own weight - the last few centimeters of closure - downhill. Due to this, such guides are very widespread. The photo of the metabox clearly shows which part of the guide is intended for what. One is attached to the wall of the furniture (small parts in the photo, bearing), the second - to the design of the drawer. In the case of metabox - the second part of the kit forms the entire side wall of the box. A box with mounted roller guides looks like this

However, the main drawback of this type of guide is the incomplete extension. The drawer can be safely pulled out at approximately 75% of the depth. Let's see what problems can most often arise with such guides. Naturally, we will assume that everything was normal in the “freshly bought” furniture.

Incorrect installation

This problem is usually diagnosed immediately, before the purchase. A box with a roller guide correctly installed in technical clearances moves smoothly, it has a fairly small horizontal clearance. It is checked simply - a practically closed box needs to be tried to "shake" left and right by the handle. If they eat more than three to five millimeters, the installation is incorrect. This can be caused by errors in the dimensions of parts during design, or it can be a technological error of the guide itself. It is no secret that in the modern furniture market there is a sea of small firms that save literally on everything. And cheap guides of dubious manufacturers often "walk" through the thickness of the gap.

Over time, such a problem may arise due to structural deformation. A heavily loaded furniture box is deformed if it is made from a slab of inadequate thickness. Again - the manufacturer saved and used the material, not thinking about the margin of safety.

It is difficult to cope with problems caused by a change in technical clearance. Here you already need to intervene in the design, to do this in 90% of cases is possible and not very difficult, but this is another rather voluminous topic.

If the box does not close on its own when sliding under its own weight, this is an incorrect installation of the bearing part of the guide. Most often, it is not installed horizontally. You don’t need to touch the front part with such a repair - we don’t want to bother with the appearance of the gables of the boxes. We turn off the fasteners - in addition to one point near the very front roller, align, screw in place. This is done with the part of the guide, which is located on the furniture wall.

Overload

This problem is not as rare as it might seem. The reasons can be either banal, such as “the manufacturer saved” or “well, they did a lot of things”, or non-standard - the children just love to climb the handles of chests of drawers like stairs or use them as a support to climb higher. And since the last thing that is being saved now is the handles, the guide suffers.

The problem can be solved in two ways.The main sign - the front wheel of the supporting part of the guide, the one that “twists” on the furniture wall - the plane ceases to be vertical, the metal is deformed in the attachment area and the wheel begins to cling to the second guide. You can return the wheel to its original position. It is not worth hammering, the roller can simply be split, but with the help of a vice, holding the sleeve, you can restore the original position of the part.

However, more often this problem is caused by the manufacturer. There are two main applicable metal thickness standards for such guides - 0.5 and 1 mm. The manufacturer could just save. Replacing the guides with thicker ones is not a problem - all places of fasteners coincide. Just remove the old ones and replace them with new ones.

The same "diseases" and the older brothers of the roller guide - metaboxes. If it seems to you that this will not help either, replace the roller guides with telescopic ones. This is pretty easy to do. Below we will talk about roller guides.

Exceeding Effective Life

Nothing can be done here. Plastic rollers, over time, they simply wear out. There is a backlash, the boxes are not so confidently open. There is only one way out - to replace. You can, of course, use silicone greases for a while, but this will not solve the problem.

Deformation of individual parts

This can happen if slides are installed carelessly. There are not enough mounting points on the load-bearing part on the furniture wall, for example. Then the guide bends, connections loose, it is tracked almost immediately. In order not to encounter such a problem out of the blue, ask the seller to pull out the drawer and make sure that the guides are attached at all points provided by the design.

The same problem can occur when the load is exceeded. In this case, the lack of proper rigid fastening will only aggravate the development of the situation. It’s easy to “heal” - to the details, most often it’s enough to return the original form and fix it properly.

Ball guides

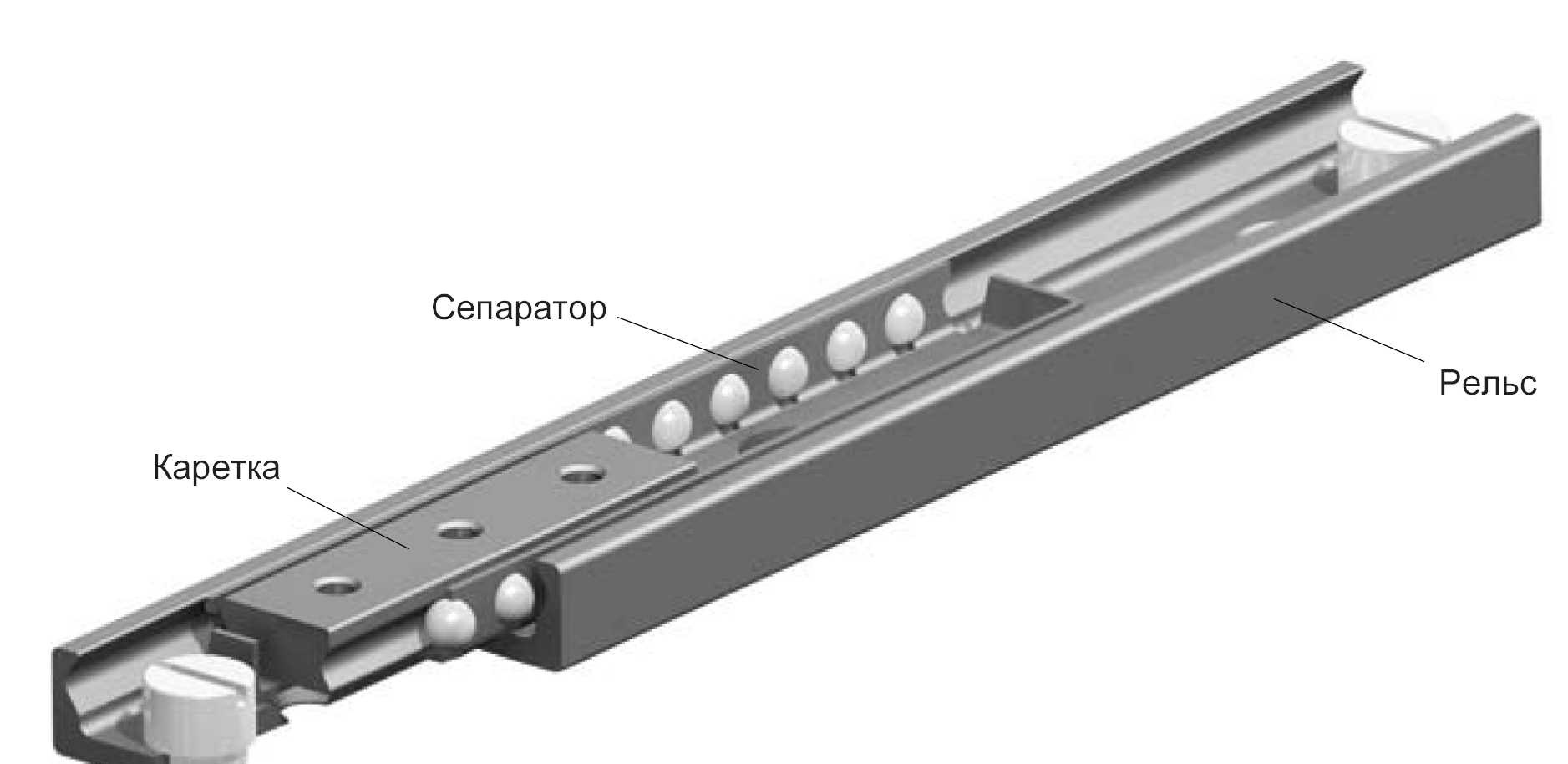

The second type of guides are ball. Or the type of "telescope." And their older brothers are the tandemboxes. They are more expensive, but devoid of all roller diseases. Therefore, they are often used by those manufacturers for whom quality is more expensive than savings. They look like this

The ball guide can withstand many times the mass. In roller - two fulcrum - rollers on the bearing part and part of the box. In a ball - a whole block (middle), on which small balls are located according to the principle of a rolling bearing. Plus, the thickness of the metal from which the parts of the guide are made is much higher. Three more notable advantages - such guides are almost impossible to put incorrectly, they allow you to push the box to the full depth and make it possible to firmly fix the box in the closed state. In addition, ball guides can be installed at any height by design.