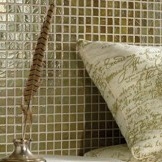

Stone crumb

Stone chips - a very interesting and unusual version of the decor of the room. Externally, the material consists of small stones, which are diluted with adhesives and binders. The material is found in a variety of colors and shades, and is available in metal or plastic containers of 15-20 kg. The crumb is granite, marble and quartz. Marble, by the way, is considered the most beautiful and, accordingly, the most popular. You can get acquainted with other types of plaster here.

Where decorative stone chips are most often used

Stone chips can be used both for internal (small stone chips) and for external works (large marble chips). In apartments and houses, the material is often used on small surfaces or used to focus on a certain part of the interior: ledges, arches, boxes, niches, etc. Also, do not forget that the crumb is quite cold material, so it is better to use it in non-residential areas: bathroom, hallway or hall.

Outside, using similar plaster, you can decorate both individual parts and the entire building. Moreover, outwardly such material looks very beautiful and noble, not inferior even to artificial stone.

Kinds of stone chips

Such plaster can be divided according to several criteria:

- Type of solvent. Stone chips exist both on the basis of an organic solvent and on a water basis. The first, by the way, is now almost never used.

- Type of filler. Here, marble granules, to which quartz or granite chips are sometimes added, are most often used as fillers. Sometimes there are plasters, in which quartz acts as a filler.

- The method of coloring granules. For a more elegant and decorative look, they sometimes use a mixture of granules of different colors. A wide selection of colors will perfectly complement any interior.

- The size of the granules. Depending on the size of the granules, marble chips are divided into groups:

- coarse (3-5 mm;);

- medium-pressure (1.5-2.5 mm.);

- fine-grained (less than 0.5 mm.);

The packaging may not indicate the exact size of the granules, but the group to which it belongs will be written there. The granules have a rounded shape, due to which they are not scratched when touched. The same material can be produced in two or more versions, the difference will be only in the size of the particles. Not only the appearance, but also the consumption of the composition depends on the size of the granules. After all, the larger the particle, the greater the consumption.

Advantages and disadvantages

- wear resistance and durability;

- does not fade in the sun;

- resistance to any weather (not afraid of heat, cold and water);

- applied to any surface: drywall, concrete, plaster, cement, etc .;

- attractive appearance;

- vapor permeability;

- longevity;

- allows the wall to "breathe";

- easy to clean;

- masks surface irregularities and defects.

And the plus and minus is the strength of the material.Indeed, over time, you can replace the old crumb only by tearing it along with the wall. It adheres so firmly that it becomes “monolithic”. Therefore, a new finishing material, whether it be paint or wallpaper, will have to be applied on top of the old one, after having previously been plastered.

Technology for applying marble chips

- First you need to prepare the surface. The wall should be smooth, clean, dry, without cavities, dents or other defects.

- Next, primed. To do this, you can use almost any paint, the main thing is to strengthen and protect the wall from moisture to avoid dampness and mold. In this case, the paint is selected in the same color as the plaster. By the way, you can familiarize yourself with all types of primers here.

- We apply the material itself. To do this, you can dilute it a little with water and mix well, then the crumb will be more "obedient". Proportions: for a capacity of up to 20 kg - 1 liter of water, up to 25 kg. - 1.5 liters. Next, we establish a part of the mass on the surface and spread it from top to bottom, while removing the excess with a spatula. More than 2-3 passes are not recommended, because pebbles can be damaged and subsequently gray spots will form on the surface. Layer thickness 1.5 - 2 crumbs. The material dries up to 12 hours.

- We are waiting for a couple of weeks to open the surface with varnish, this will help maintain an aesthetic and beautiful appearance for many years.