How to make wire connections

Correctly made connections are one of the whales on which a long and high-quality wiring service is supported. What you need to know in order to make your wiring guaranteed to last for many years.

We will not delve into the jungle of calculations and calculations, but turn to ordinary common sense. If we draw an analogy between the electric current and the flow of water in pipes (adjusted for the flow velocity, which is equal to the speed of light for electric current), then the first law of electricians will immediately become clear - first of all, violations in the electrical circuit must be sought at the joints. And in fact - in a whole pipe, the water will simply flow to itself, and on bends and joints it will hit obstacles. And water, as you know, grinds stones. Continuing the analogy, I’ll inform you that enterprises and factories should be checked and retaken annually everybolted connection in electrical circuits, especially those that are under significant load.

What should be a good wire connection?

One that freely passes through itself an electric current. If the cross-section of the wires, for example, is 2.5 mm², then the contact area of the connected wires, respectively, cannot be less than the indicated value. This is simple to achieve - we strip the length of the wire 10 times longer than its cross section (without a square) for twisting. In this case - 2.5 cm. In practice, of course, it would never occur to anyone to measure the area of contact, and the wires are stripped just by eye.

Twist Lock

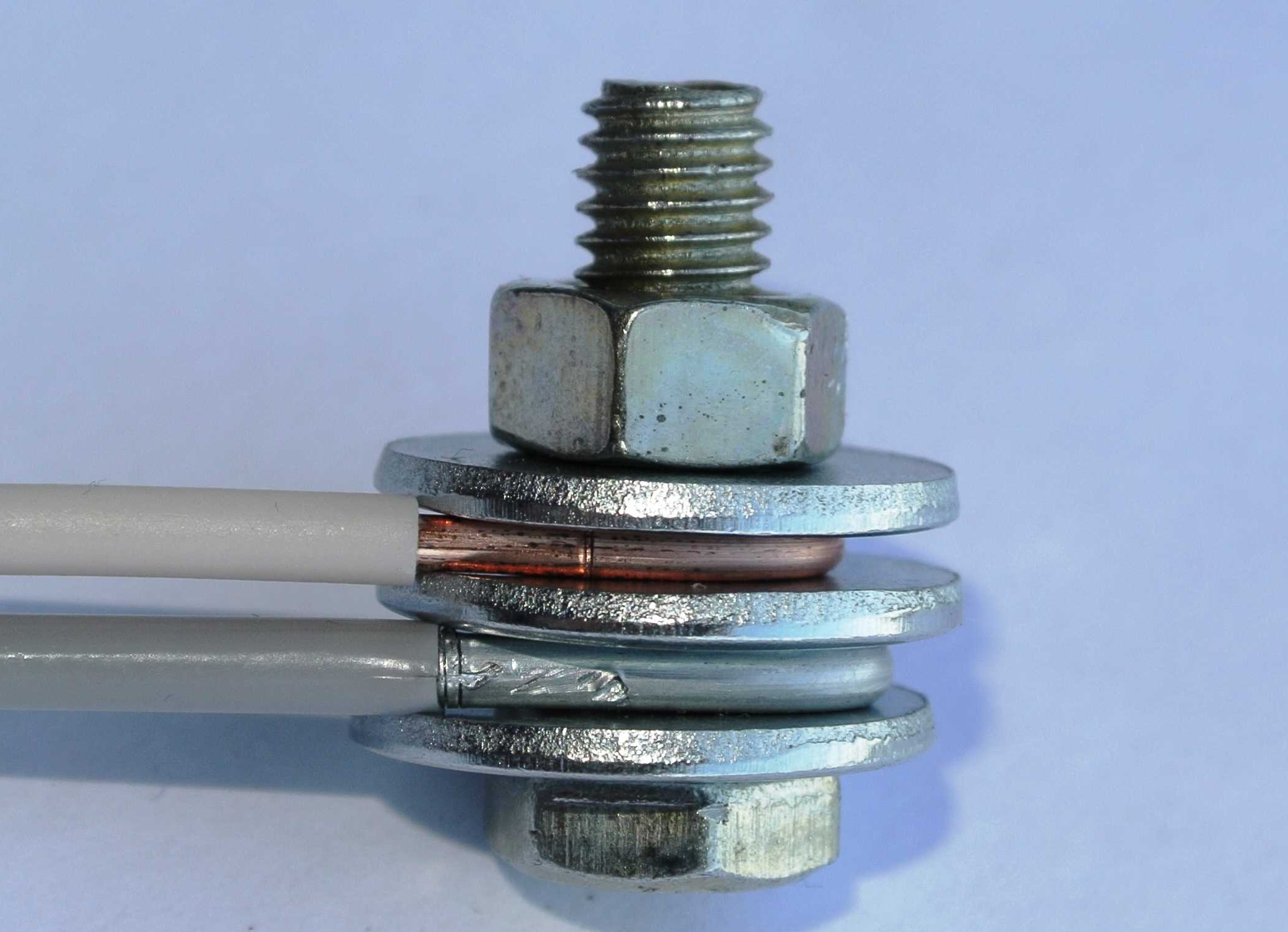

Wires must be tightly pressed together - not even the slightest play of twisted ends is allowed. If the touch is loose, then this place will be constantly prone to the occurrence of discharges of micromolines. If you are lucky, the connection will simply “skip” and serve a little more. In most cases, the place begins to heat up very much, melts the insulation with all the ensuing consequences (the result is about the same as if a match were lit there). Therefore, if this is a twist of wires, then we bend the ends and use pliers to help ourselves tighten the wires as tight as possible (without fanaticism, of course, all the same copper is a soft metal), if this is a bolted connection, then we must use a washer (to increase the contact area) and a grover preventing contact from loosening.

After twisting, we bend the resulting 2 cm twisted round in half and carefully crimp with pliers. The twist is ready - you can isolate it.

Twisting is used for small values of the cross section of the wires. If 1.5 - 6 squares can still be twisted and squeezed qualitatively, then a wire of 10 mm² must already be connected through a bolted connection or through special couplings. In the first case, the ends of the wires are bent by a ring, a washer, wires, another washer are put on the bolt, and the entire contact is tightened with a nut. In the second case, the ends of the wires are inserted into different ends of the coupling and clamped by bolts.

Note! For a long time there was debate about which wire to use when installing electrical wiring - single or multi-core (inside the insulation there is one thick monolithic core, or many thin veins twisted into one thick). No one will give you an exact answer today - you can do this and that. We only note that the single-core wire is designed to be laid and not touched, and the multi-core wire is made for installation also on moving objects. The only problem that sometimes arises with stranded wires is that it is not possible to clamp their entire area with a bolt (when attached to a socket or switch). In this case, additional terminals come to the rescue, which are put on the stripped section of the wire, and then pressed together with pliers.As a result, we get a stranded wire with a single-core tip, which can be safely clamped with a bolted connection.

We connect copper and aluminum

Any electrician will tell you that you cannot connect aluminum and copper wires. And if you can’t, but really want / need ... then there is a way. Why can not these metals be combined? Because they have different chemical activity, and at the place of their connection, the oxidation reaction begins, which worsens and then destroys the contact. But what if you have to make such a connection for a long time? There can be several solutions, but for domestic conditions the simplest and most reliable is to use a gasket made of a third metal. It is done like this. We clean the ends of the wires and bend them with a ring. Take a bolt, put a washer on it, one of the wires, one more washer, another wire, a third washer, a grover, and clamp it all with a nut. Done - you can isolate and use.

It is only necessary to carefully watch the cross-section of the wires. Because copper conductivity is better, if the current flows from a copper conductor to aluminum, then the cross section of the latter should be an order of magnitude thicker, otherwise there will be a situation similar to welding pipes of different diameters - there will always be a pressure drop at the junction.